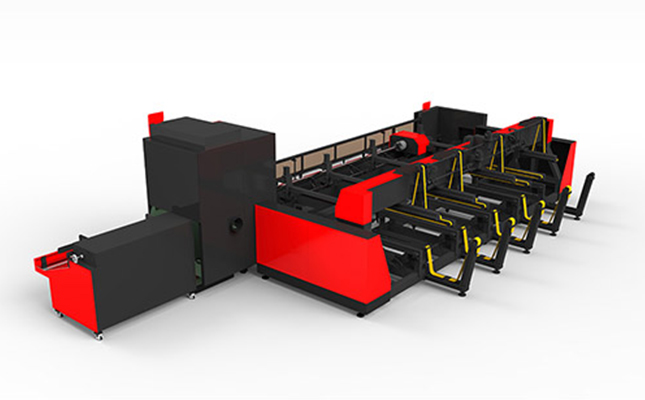

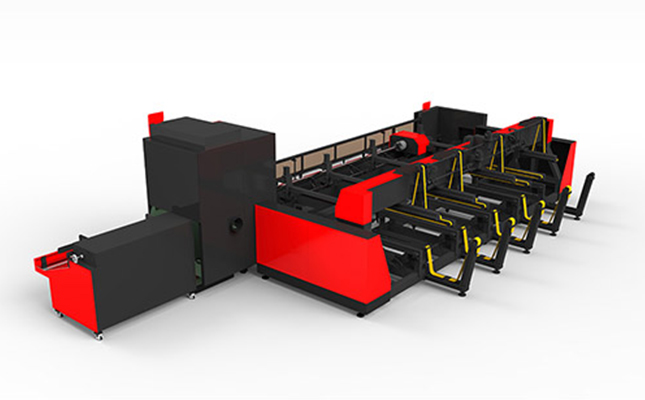

Fiber Laser Tube Cutting Machine

Our professional fiber laser tube cutting machine is mainly used

Home » Tube and Pipe Laser Cutting Machines

Our professional fiber laser tube cutting machine is mainly used

The fiber laser tube cutting machine fully automatic, can cut

The tube laser cutting machine semi automatic is equipped with

The tube and pipe laser cutting machines are rapidly popularized in the market because of its high metal tube production and exact contour accuracy. It can also realize the chamfering, hole making, scoring, other possible operation and complex structures etc. The clamping chucks hold the material in place and make the synchronized rotational motion to feed the material for the operation. The centrifugal force of chuck rotation ensures stability, avoids gravity deformation and modular design avoids the replacement of functional components often. It can process various contour shapes on the surface of the pipes & profiles, cut based on the design requirement quickly and liberate the labor needs Also, it cuts several meters of pipe in one minute which is unmatched by conventional processing methods.

The tube laser cutting machine is capable to cut various metals such as stainless steel, carbon steel and aluminum etc. It can provide a smooth output end face and non-contact processing nature that prevents material deformation or contamination. The delivery time is very short and can cut almost any size, type & shape of pipes. It is completely controlled by a computer which avoids the interference of humans and improves the production results. This tube and pipe laser cutting machines three dimensional rotating head creates an accurate cut, greatly saves costs, maximizes the yield of raw materials and creates output parts ultra-efficiently. It boosts performance, automated functions improve ease of operation, extensive range of cutting capabilities and ideal for many varieties of applications.

Get in touch

The question or Assistance? Reach us by filling out the form. We will be happy to help and answer all inquiries from the clients.

Join Our Mailing List

Business Point International is the leading industrial machine supplier of fiber laser, metal fabrication, digital printing & wood cutting machines.

© Copyright 2013 – 2023 Business Point International. All Rights Reserved.

WhatsApp us

We will respond quickly to your valuable inquiry for clear understanding and offering services round the clock across various geographical locations!