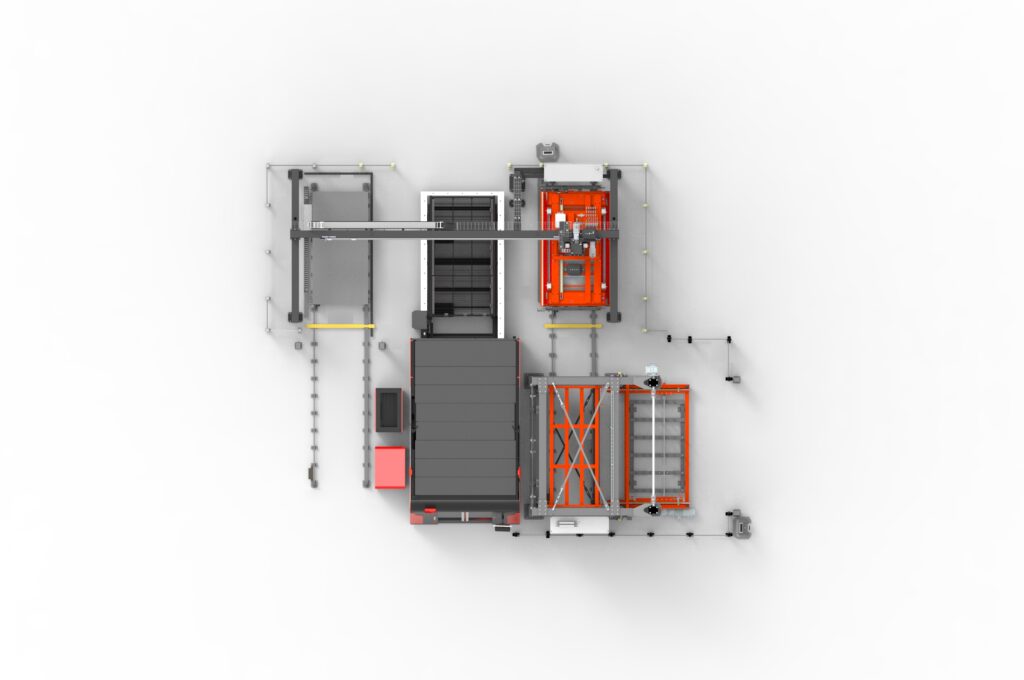

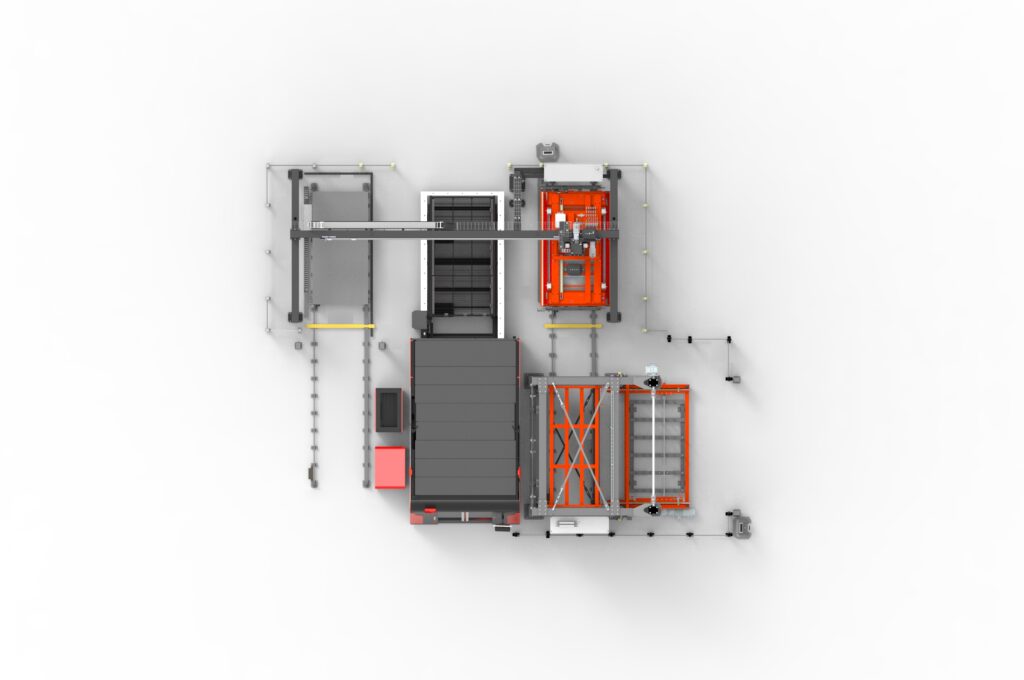

Automatic Loading & Unloading System

Our D-Trans/Tower is an automatic loading and unloading

Home » Combined Sheet Metal & Tube Cutting Machines

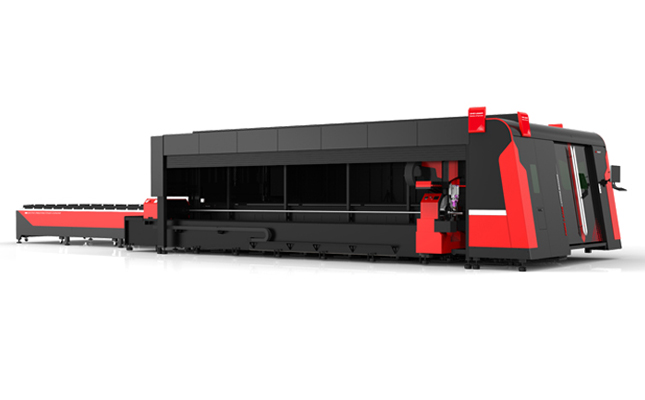

In the metal processing industry, the demand for processing the various sheet metals, tubes, pipes & profiles rapidly increased so the industries preferred sheet metal and tube cutting machines. It has the advantage of processing the metals and pipes in a single machine so this efficient machine proves to be a wise investment for the metal processing business. The CNC machinery has a high level of control & precision, no thermal affecting zone, makes cleaner cuts and does revolution with massive production. This guaranteed efficiency of the laser cutting machine ensures the perfect delivery times, reduces cost and gives complex productive output parts.

Our D-Trans/Tower is an automatic loading and unloading

Our plate and pipe laser cutting machine fulfills the demand

Our integrated plate and tube laser cutting machine is specially

The numerical control guides the laser operation to take place at a fast speed, intelligence has been increased, cutting design instructed by programming software and batch processing is possible at one time. Sheet metal and tube cutting machines can process the different shapes & sizes of parts to meet the requirement of various industries and the accuracy is significantly improved. In the tube cutting, it cuts different types of pipe thickness & diameter and makes angel cuts, bevel cuts & slots. It is adopted with a chuck to clamp the material according to its specification and can hold the pipe shapes such as square, round, circle & other special-shaped pipes. The clamping helps to complete the several tube meters of operation steadily without damage and assists for batch processing.

The sheet metal and tube cutting machines, it is using the laser source with a smaller focused spot to process the metal with finer lines. It has higher work efficiency, better output quality and produces no distortion. The edges are almost flawless, do not require additional cleaning or shaping, maximize throughput to create custom cuts and deliver a wide variety of metal & tube cutting possibilities in various industrial applications. This upgraded technology combines tube processing and sheet cutting together with an automatic control that avoids human intervention and labor charges will be saved. The one machine with multiple functions fulfills the customer’s requirement, saves the cost of purchasing two machines, minimizes the need to operate multiple machines and is space-saving in the workshop.

Get in touch

The question or Assistance? Reach us by filling out the form. We will be happy to help and answer all inquiries from the clients.

Join Our Mailing List

Business Point International is the leading industrial machine supplier of fiber laser, metal fabrication, digital printing & wood cutting machines.

© Copyright 2013 – 2023 Business Point International. All Rights Reserved.

WhatsApp us

We will respond quickly to your valuable inquiry for clear understanding and offering services round the clock across various geographical locations!