Home » Fiber Laser Cutting Machines

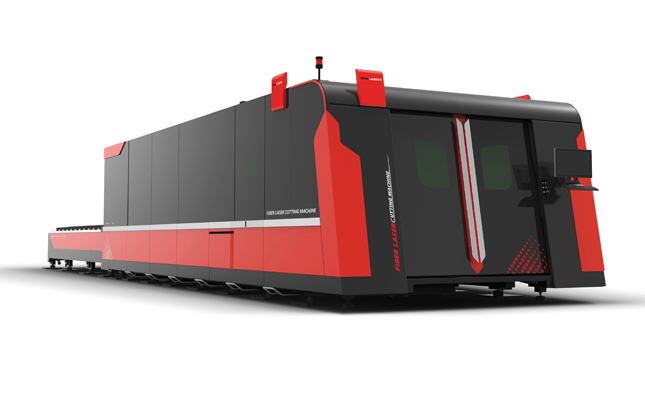

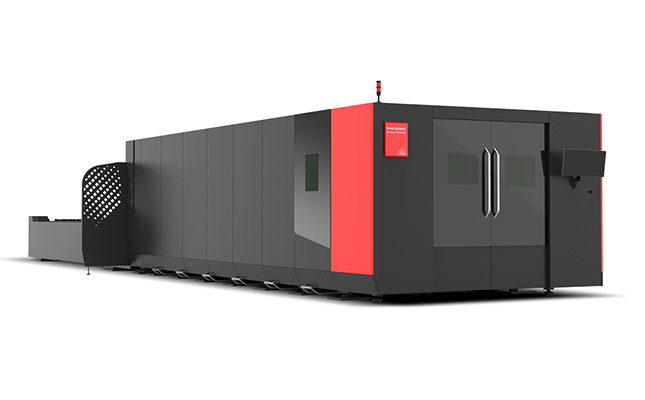

The D-Soar ultra high power fiber laser cutting machine has become the

D-Solar Ultra High Power metal laser cutting machine is the advanced laser

Our D-Win open & close type sheet metal laser cutting machine is

The CNC fiber laser cutting machines do not deform due to vibration or temperature change. The structure is more compact, convenient to operate and can adjust the frequency, polarization & phase. It is quite easy to customize the spectrum so the producing energy is concentrated to result in a flexible shape and highly controllable. The source & high-energy beam improves the service life of the machine, achieve stable infrared output and rightly serve as a perfect laser solution. It significantly shortens the production cycle, eliminates material waste, reduces labor cost and destined to bring a revolutionary breakthrough in the metal processing industry.

This fiber laser cutting machines are unique in metal cutting, levels no burrs or kerf, non-contact process avoids scratches on the material and effective processing of large & thin-walled parts to the final products. It gives a series of safe operation, smooth cutting surface, makes marvelous & intricate designs with enough detailing and fine-tuned for the required operation. The high-powered beam focuses on the material surface, melts or vaporizes the targeted area to cut and it is completely controlled by a numerical & mechanical system. The head moves to locate the spot automatically according to the output design, broadening versatile capability and neat to meet the industrial needs. Also, the head won’t touch the material that protects the workpiece from scratching and ensures precision. It has more energy conversion rate that reduces operational and maintenance costs.

Get in touch

The question or Assistance? Reach us by filling out the form. We will be happy to help and answer all inquiries from the clients.

Join Our Mailing List

Business Point International is the leading industrial machine supplier of fiber laser, metal fabrication, digital printing & wood cutting machines.

© Copyright 2013 – 2023 Business Point International. All Rights Reserved.

WhatsApp us

We will respond quickly to your valuable inquiry for clear understanding and offering services round the clock across various geographical locations!