Plate and tube laser cutting machine is the advanced versatile equipment which is used in various industries for the precise cutting of both flat sheets, tubes and pipes. These machines utilize fiber laser technology to deliver exceptional accuracy, making them indispensable in modern manufacturing processes. With its ability to handle different materials and complex designs, it has revolutionized the way metal components are produced and offers numerous benefits such as increased productivity, reduced waste and improved quality. The laser technology employs to achieve unparalleled precision, ensures intricate cuts on various materials and allows for a wide range of applications across different output functioning. The high-speed cutting capabilities are significantly enhancing productivity, enabling manufacturers to meet tight deadlines quickly with increased output. By eliminating the limitations of traditional cutting methods, laser cutting machines deliver superior quality cuts, ensuring consistency and precision in every single output produced. Let’s delve into the world of sheet metal and pipe laser cutting machine to explore their components, advantages and industrial applications.

Working Components of Plate And Tube Laser Cutting Machine

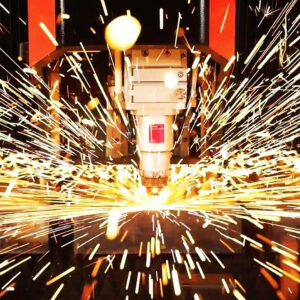

● Laser Source

The laser source generating the high intensity of laser beam which providing the energy required for the processing and determining the cutting speed & accuracy. After it emit the material, causes instant melting or evaporation to cut off the required design from the material.

● Cutting Head

The cutting head is designed with nozzles to deliver the laser beam to the material. It also has additional features such as automatic height control to protect the workpiece from the deformation and sensing systems to maintain the optimal cutting conditions. Also, has automatic focus function to calculate the exact focal length.

● CNC Controller

The computer numerical control (CNC) system is responsible for controlling the entire cutting process. Receiving codes from the users, converting into machine readable code then controlling the head movement & other functioning components and helps for continuous repeatable cuts.

● Worktable

The working table is designed sturdy flat surface for the material being cut. It also has automated loading and unloading systems to enhance productivity.

● Chuck

The automatic pneumatic chuck is designed for realizing of quick clamping that rotating and driving the workpiece for the operation. It can handle thin to thick walled pipes, featured with automatic centering in the rear & front end and higher repeat positioning accuracy.

● Control Panel

The control panel is using to interact with the machine easily, gives a user-friendly interface by inputting the processing parameters and monitoring the operation. Helps for perfect operation, highly reliable to get the exact pattern and improves the human & machine contact.

● Cooling System

The cooling system is using to cool the laser source & other components, maintains the temperature and ensuring its longevity & performance. It has an overheat protection system to protect from thermal deformation and prevents from the material wastage during operation.

Advantages of Plate And Tube Laser Cutting Machine

● Versatility

● Versatility

Plate and tube laser cutting machines are versatile, capable of cutting a wide range of materials, including various metals such as stainless steel, aluminum & mild steel etc and . They can handle both flat plate materials and cylindrical tubes or pipes, making them suitable for a diverse range of applications.

● Precision

Laser cutting technology provides exceptional precision in cutting, focused laser beams to create clean and high-quality cuts with tight tolerances. This level of precision allows for intricate designs, complex shapes, tight fit-ups, ensuring consistent and accurate results.

● Efficiency

Laser cutting machines are known for their high cutting speeds, which significantly improve productivity. It can process materials quickly, reducing production time and increasing overall efficiency. They offer faster turnaround times compared to traditional cutting methods and enabling faster completion of projects.

● Automation

Equipped with advanced automation features. These include automatic material feeding systems, automatic height detector and integrated CAD/CAM software for precise design. It streamlines the cutting process, minimizes human error, and maximizes efficiency.

● Flexibility

Plate and tube laser cutting machines provide excellent design flexibility, allowing for intricate and complex shapes to be cut with ease. They can handle both straight cuts & 3D cuts, enabling the creation of unique and customized parts. This flexibility gives designers and fabricators the freedom to bring their creative ideas to life.

● Minimal Waste

Highly efficient process that minimizes material waste, narrow laser beam width allows for exact cutting and reducing the amount of scrap material generated. Additionally, advanced nesting software can optimize the layout of parts on the material sheet or tube, further maximizing material utilization and reducing waste.

● Smooth Cuts

Plate and tube cutting machines produce clean cuts with minimal burrs, reducing the need for additional post-processing or finishing. The laser beam melts the material, resulting in smooth edges and clean-cut surfaces, eliminating the need for secondary operations and saving time and resources.

● Environmentally Friendly

Results clean and environmentally friendly cutting process. It produces minimal dust, fumes, or harmful emissions and making it a greener option compared to traditional cutting methods. The reduced material waste also contributes to a more sustainable manufacturing process.

The Bottom Line

In conclusion, plate and tube laser cutting machines have emerged as crucial tools in the realm of the manufacturing and fabrication industry. The adoption of these machines has led to significant advancements in metal processing. As technology continues to modernize, our machinery is expected to become more capable, furthermore revolutionizing the industry and enabling the production of intricate metal components with ease. This level of precision is especially crucial for industries such as automotive, architectural, fabrication, medical equipment and aerospace etc. It provides the end final product without having the smallest deviation or deformation and creates a diverse range of component structures. This versatility opens up a world of possibilities for the production of customized parts, intricate patterns and complex geometrics.

Whether it is sheet metal processing or fabricating tubes structure, it provides the flexibility required to meet the demands of various industries. Automating the cutting process eliminates the need for manual labor, resulting in massive productivity and cost savings. Additionally, precise plate and tube laser cutting machine cuts achieved by laser cutting machines minimize material waste, maximizing the utilization of raw materials and reducing environmental impact. For the new possibilities of material manufacturing, reach Business Point International in UAE. We are supplying top-quality industrial machinery at your facility. Please feel free to reach us to know more!