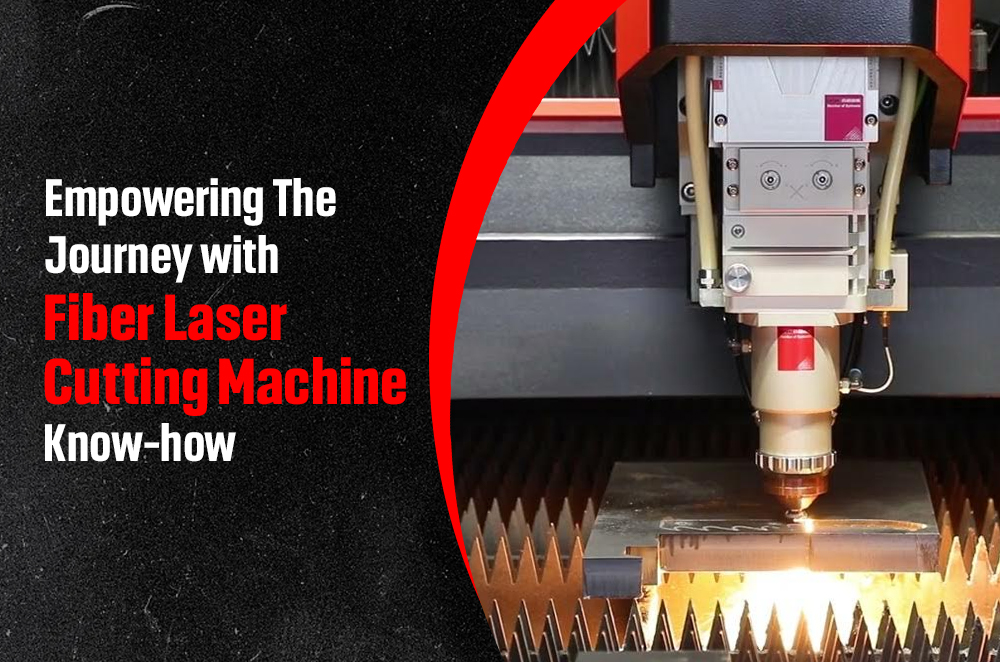

The fiber laser cutting machine utilizes a high-intensity laser beam which is generated by a laser source to precisely cut through various materials with exceptional speed. Unlike traditional CO2 lasers which get support from gas amplification, fiber lasers are composed of optical fibers. It offers several advantages including higher efficiency, better beam quality and better reliability. The laser cutting machine begins with the generation of a laser beam within the laser source. The laser beam is transmitted through a flexible fiber-optic cable to the print head, it is focused onto the workpiece. As the fiber laser interacts with the material surface, generates intense heat and causes melting & vaporization. The high-pressure laser is directed onto the cutting zone to blow away molten material and create a clean, precise cut.

The key advantage of fiber laser technology has the ability to cut a wide range of materials with precision. The commonly processed materials include metals such as steel, aluminum, stainless steel and copper. It is capable of cutting various thicknesses, ranging from thick to thick steel plates and making it suitable for a diverse range of applications across different industries. This machine works by utilizing the high-intensity powerful light beam generated by a fiber laser which melts or evaporates the workpiece along a precise path. It results in accurate cuts. Here we are breakdown of how the process typically works:

Generation of Laser Beam: The working principle starts with the generation of the laser beam within the fiber laser source. The resonator contains a laser-active medium, stimulating the emission of power to cut the material.

Amplification and Delivery: The generated power passes through the optical fiber, resulting in a highly intense and coherent beam of light. Then, the beam is delivered through the fiber optic cable to the cutting head for processing.

Focusing the Laser Beam: The lenses or mirrors focus the laser beam to a tiny, extremely high-energy point called the focal point which is present in the cutting head. This highly concentrated beam is directed to the material surface to be cut.

Material Interaction: The focused laser beam reaches the material, it instantly heats it to the point of vaporization or melting. The workpiece absorbs the laser energy, causing it to reach the melting temperature almost rapidly.

Cutting Process: As the laser beam moves across metal with the predetermined cutting path, it continuously melts the material along its trajectory. It is typically used to blow away the melted or vaporized material to create the cut on the material.

Control and Precision: The cutting head movement of the fiber laser and the intensity of the beam laser are controlled by a computerized numerical control (CNC) system. It reads the cutting or processing instructions from a design file, translates them into precise movements and sets the laser to achieve the desired cut.

Cooling and Waste Removal: Excess heat is generated both in the material being cut and the components of the machine, during the cutting process. A cooling system is deployed to dissipate the heat and maintain optimal operating conditions. Additionally, waste material and debris produced during operation are removed by using a combination of gas assist and suction systems.

Completion and Quality Assurance: After the completion of the process, the finished workpiece will go under inspection for quality and accuracy. Fiber laser cutting machines are known for their high repeatability and have the ability to produce clean edges without the requirement of any subsequent processing in many cases.

Overall, fiber laser machines provide a highly efficient, precise and versatile method for processing a wide range of materials including stainless steel, carbon steel, copper, aluminum, nickel, manganese & other metal types. This machine is essential in various industries such as manufacturing, automotive, aerospace and electronics.

Exploring Future Trends in Fiber Laser Cutting Machine Technology

● Introduction

Fiber laser cutting machines are revolutionizing the manufacturing industry with their high precision. As technology advances in processing, several trends in industries are shaping the future of laser cutting machines which promise greater efficiency, reliability, flexibility and modernized capabilities. In this blog, we delve into the key trends expected to drive the evolution of the machine in the coming years.

● Enhanced Automation and Integration

Automation is a significant trend across various industries and the realm of laser cutting machines is no exception. Future machines are probably to include superior automation functions with automatic nozzle changers and clever workpiece positioning structures. Integration with high-standard components will allow seamless connectivity, allowing machines within the production technique and optimizing manufacturing workflows.

● Intelligent Control Systems

The improvement of sophisticated systems is poised to play a crucial position in the evolution of the fiber laser reducing era. CNC techniques will allow real-time monitoring & adjustment of cutting parameters, leading to improved performance, higher pleasant cuts and decreased cloth waste. These sensible control structures can decorate predictive maintenance skills, making sure minimum downtime and maximum productiveness.

● Multi-Material Processing

While fiber lasers have historically excelled in reducing metals wastage which includes steel, aluminum and stainless steel, future trends advise a growing call for multi-material processing competencies. Advanced fiber laser slicing machines might be designed to address a broader variety of materials. This enlargement of talents will cater to numerous enterprise requirements and open up new opportunities in diverse sectors.

● High Power and Speed

Advances in fiber laser technology are driving the development of fiber lasers with higher power and faster cutting speeds. This machine is expected to deliver higher wattage, enabling ultrathin cuts while maintaining accuracy and edge quality Advanced beam delivery systems and optics will further increase cutting speeds, enabling fiber laser cutting devices has be efficient and cost-effective

● Compact and Modular Design

Space optimization and flexibility will be key considerations in the design of future fiber laser cutting machines. Manufacturers can focus on compact modular systems that can be easily integrated into various products including small factories and large manufacturing facilities. Modular systems will provide flexibility and customization, enabling businesses to gain improvements in laser cutting capabilities and can adapt to different needs & requirements.

● Environmental Sustainability

As environmental concerns become more apparent, the construction industry is moving towards more sustainable practices. Fiber laser cutting technology is well positioned to match this trend, due to its inherent energy efficiency and low waste. Future models will have to incorporate features such as energy recovery, efficient dust & smoke filters and environmentally friendly exhaust systems for the environment to significantly reduce environmental footprint and increase sustainability.

Conclusion

The future of fiber laser cutting machines promises exciting developments that will drive innovation and transformation across industries. From enhanced automation to intelligent control systems to more resource consumption and environmental sustainability, these trends are set to reshape things if it is carried out to enable businesses to reach new levels of productivity, equity and competitiveness.

Case Study and Control Data of Fiber Laser Cutting Machine

Introduction

Fiber laser cutting machines have transformed industries, enabling businesses to achieve greater accuracy, faster material speeds and increased productivity. In this article, we will explore real-world examples of businesses that have benefited from fiber laser cutting, unique applications and innovative applications of this versatile technology.

Real-world examples of businesses benefiting from fiber laser cutting machines

Space Services

Company X

Case Study: A leading aerospace company is using fiber laser cutting machines to improve production efficiency. By using a fiber laser to cut aircraft parts such as aluminum and titanium sheets. The company has significantly reduced the processing time and improved the accuracy of cutting materials. It results in cost savings and has increased productivity and enabling to meet tight deadlines while maintaining high standards in aircraft manufacturing.

Automotive Services

Company Y

Case Studies: The company uses sheet metal laser cutting machine in its automotive plants to precisely cut sheet metal components used in automotive bodies. With the adoption of fiber laser technology, it has enhanced its manufacturing processes to simplify, reduce waste and achieve faster turnaround times for assembly vehicles. It also enables manufacturing capabilities which supports commitment to innovation and customization.

Medical Device Manufacturing

Company Z

Case Study: A global leader in medical device manufacturing relies on fiber laser cutting machine to produce complex components for surgical instruments, implants and medical devices. Fiber lasers provide unparalleled accuracy & efficiency, enabling company to deliver high quality products to healthcare providers and patients. The speed and efficiency of fiber laser cutting enabled it to reduce manufacturing costs. It has also provided life-saving medical technologies have been able to accelerate time to market

Special Applications of Fiber Laser Cutting Machine

Textile Industries

Company A

Case Study: The famous sportswear manufacturer has adopted fiber laser cutting technology to precisely cut fabrics and designs. Fiber lasers enable the creation of incredible shapes, patterns and air holes with unprecedented accuracy & speed. It has revolutionized the design and manufacture of products, giving athletes and consumers a wide variety of customization options.

Arts and Crafts

Case Study: Digital artist and sculptor incorporates fiber laser cutting machines into his creative process to create masterpieces & kinetic sculptures While using precise and versatile fiber lasers the role, can cut a variety of materials and inscribe with the limits of traditional art forms was able to push and explore new possibilities in digital design & communication systems

Jewelry making

Company B

Design: A renowned fine jewelry brand uses fiber laser cutting machine to create intricate designs and details in precious metals. It has the ability to achieve unparalleled precision and detail in their jewelry designs from patterns to individual engravings. This advanced technology allows the company to achieve the highest level of accuracy and detail. It is providing customers with custom jewelry that is beautifully designed and meticulously finished.

Conclusion

These case studies and examples highlight the various applications and important benefits of metal laser cutting machine in various industries. From aerospace and automobiles to medical device manufacturing as well as its unique applications in textiles, art and jewelry. Fiber lasers have become an indispensable tool for achieving precision, efficiency and innovation to increase and open up competition with other possibilities in their respective fields.

To Reiterate The Importance of Fiber Laser Cutting Machines

Fiber laser cutters have emerged as indispensable equipment in modern manufacturing, offering unparalleled accuracy, speed and versatility. We have explored real-world examples and case studies that highlight the significant impact of fiber laser technology in various industries.

In the aerospace industry, companies have used fiber lasers to streamline manufacturing processes and meet stringent quality standards in the aviation industry. Company have benefited from fiber laser cutting machine to enhance manufacturing performance. Important applications in protective medical technology rely on fiber lasers to ensure accuracy and stability

Furthermore, fiber laser cutting machines have found distinct applications in creative fields such as textile manufacturing, art and jewelry making. Artists and designers use fiber lasers to push the boundaries of traditional art forms and explore the new possibilities of digital manufacturing and create incredible pieces with high resolution & precision.

The importance of laser cutting machine extends beyond mere design and efficiency. These advanced fiber laser technologies enable businesses to innovate, improve quality and differentiate their products in an increasingly competitive market. By harnessing the potential of fiber laser machines, manufacturers can unlock new opportunities for growth, improve productivity and increase customer satisfaction.

Final Thoughts on The Future of Technology

Looking ahead, the future of fiber laser cutting technology looks promising, with industries poised to further innovation and transformation. As the technology continues to evolve, can look forward to fiber laser cutting machines becoming more efficient, more flexible and able to meet emerging challenges & opportunities.

Key features like enhanced automation, intelligent control systems and multi material processing capabilities will shape the development of fiber laser cutting technology in coming years. Automation will provide seamless integration with other manufacturing processes, while intelligent control systems will optimize cutting parameters for improving efficiency and quality. It will open new applications and markets for laser cutting machines.

Furthermore, advances in power generation, transmission speed and environmental sustainability will make fiber laser technology more attractive. High-power lasers will provide faster cutting speeds and increase productivity, while environmentally friendly features such as energy recovery systems, flying dust extractors effectiveness will reduce environmental impact and support sustainable production

In conclusion, fiber laser cutting machines continue to play an important role in automotive innovation, efficiency and competitiveness in various industries. By staying ahead of technological developments & embracing emerging trends, companies can harness the full potential of fiber laser technology to stay ahead of the curve and achieve sustainable success regularly in the global market.