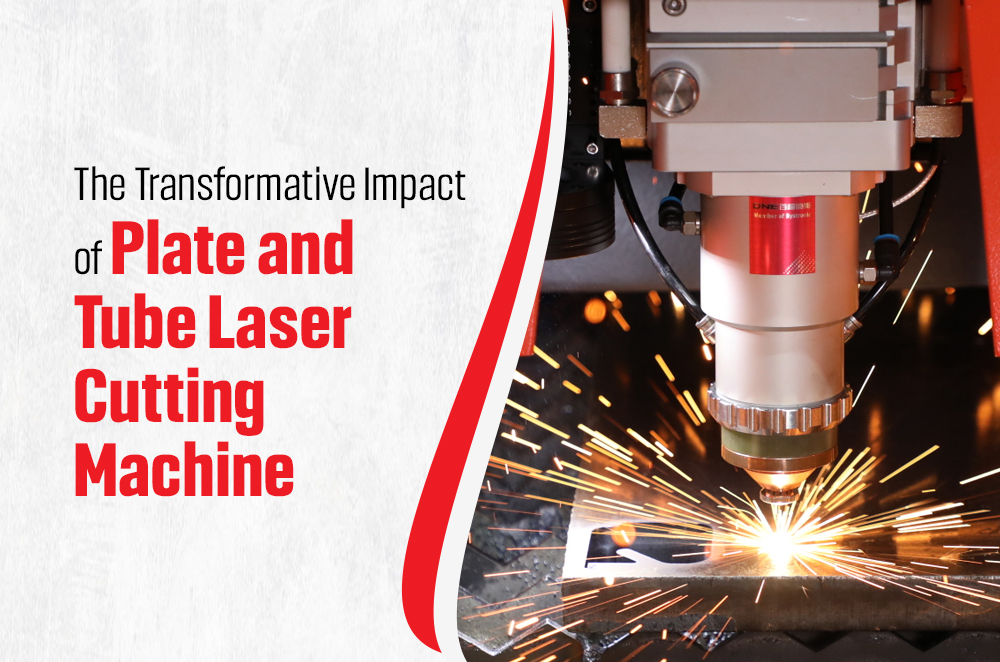

In today’s rapidly evolving industrial environment, flexibility and self reliance are becoming more important than ever. Manufacturers across the UAE are facing global supply chain challenges, rising logistics costs, and increased customer demand for faster turnaround times. In this context, the shift towards localized manufacturing is not just a strategy, it’s a necessity. One of the technologies leading this transformation is the plate and tube laser cutting machine. Known for its ability to process both flat sheets and cylindrical tubes, this machine combines two essential fabrication capabilities into a single powerful unit.

As manufacturers look to enhance efficiency and minimize operational costs, this dual functionality system is emerging as a smart investment for both established factories and new age industrial startups. With its unmatched precision and adaptability, the plate and tube laser cutting machine enables businesses to reduce dependency on third party services. Whether you’re a fabricator producing structural frames, a signage specialist cutting intricate patterns, or a metal workshop supplying custom parts, this machine helps you do more with less. As we explore how this technology is shaping localized production, we’ll uncover the real world advantages of owning a versatile laser system. From urban micro factories to scalable business models, the benefits go far beyond cutting metal, they cut inefficiency, costs, and time.

As manufacturers look to enhance efficiency and minimize operational costs, this dual functionality system is emerging as a smart investment for both established factories and new age industrial startups. With its unmatched precision and adaptability, the plate and tube laser cutting machine enables businesses to reduce dependency on third party services. Whether you’re a fabricator producing structural frames, a signage specialist cutting intricate patterns, or a metal workshop supplying custom parts, this machine helps you do more with less. As we explore how this technology is shaping localized production, we’ll uncover the real world advantages of owning a versatile laser system. From urban micro factories to scalable business models, the benefits go far beyond cutting metal, they cut inefficiency, costs, and time.

Versatility = Independence: The Strategic Value of Plate and Tube Laser Cutting Machine

In a competitive industrial landscape, the ability to do more with fewer machines defines a business’s strength. A plate and tube laser cutting machine offers exactly that advantage. Unlike single purpose systems, this dual capability machine allows manufacturers to handle both flat metal sheets and round or square tubes, all with the same equipment.

This versatility means one investment opens the door to multiple applications. You can create flat signage panels in the morning and cut structural support tubes in the afternoon, without swapping machines or tools. For manufacturers trying to reduce outsourcing, the plate and tube laser cutting machine provides a level of independence that’s hard to match.

Transitioning to a dual function system reduces idle time and increases throughput. Since switching between plate and tube operations is software controlled, there’s no need for manual reconfiguration. This not only shortens production time but also minimizes error margins and improves part accuracy. As a result, you can take on more projects while maintaining consistent quality.

Moreover, the space saving design of these machines helps businesses operate even in compact environments. Workshops in urban centers, industrial zones, or even converted warehouse spaces can benefit. A plate and tube laser cutting machine replaces two separate machines, reducing floor space requirements and simplifying training for operators.

For businesses looking to serve multiple sectors, such as construction, automotive, furniture, and metal art. This machine unlocks diverse revenue streams. Instead of specializing in just one format, manufacturers gain the flexibility to pivot and adapt to market demand. In essence, owning a plate and tube laser cutting machine transforms your facility from a limited service workshop into a full capacity metal processing center. That’s independence in the truest industrial sense.

Micro Factories and Urban Workshops: A New Industrial Model Powered by Plate and Tube Laser Cutting Machine

A new wave of industrialization is reshaping how and where manufacturing happens. Traditional large-scale factories, while still essential, are no longer the only players. Across the UAE, compact manufacturing units, often called micro factories or urban workshops are rising in popularity. And at the heart of many of these agile setups lies one powerful tool, the plate and tube laser cutting machine.

Unlike bulky production lines that require massive infrastructure, a micro factory can thrive in a space as small as 500 to 800 square feet. Equipped with a single plate and tube laser cutting machine, such facilities can handle varied tasks like cutting, prototyping, and batch production, all without the overhead costs of traditional setups. This model fits perfectly into the UAE’s dense commercial zones, where real estate is limited and expensive. Small manufacturers can now set up near their client base, allowing faster delivery times and more responsive service. Whether in Abu Dhabi, Sharjah, or Dubai’s industrial outskirts, these agile units support localized demand while staying lean.

Furthermore, the plug and play design of most modern laser systems simplifies the setup. A team of just two trained operators can run full shifts, maintaining high throughput with minimal manpower. This is a major win for SMEs or startups trying to build a sustainable business without high labor costs.

By integrating the plate and tube laser cutting machine into a micro factory model, manufacturers can shift from reactive to proactive production. They gain control over schedules, quality, and customization. All while keeping capital and operational expenses under control. This isn’t just a new way to cut metal, it’s a new way to think about industrial growth.

Empowering Entrepreneurs with Plate and Tube Laser Cutting Machine

Industrial manufacturing was once seen as too capital intensive for small startups. However, the plate and tube laser cutting machine is changing that by offering multi functional capabilities in a compact, cost effective format. Instead of investing in separate machines for plate cutting, tube processing, and manual setups, entrepreneurs can now manage all these tasks with one smart system, saving both space and money.

These machines also feature intuitive software and automated controls, making them accessible even to those without an engineering background. With rising demand for custom items like signage, furniture, and metal décor, entrepreneurs can tap into niche markets that larger manufacturers may overlook. For many in the UAE, the plate and tube laser cutting machine is more than equipment, it’s a gateway into profitable, modern manufacturing.

Sustainability and Waste Reduction in the UAE Context with Plate and Tube Laser Cutting Machine

As environmental awareness continues to grow in the UAE, manufacturers are under increasing pressure to reduce material waste, energy consumption, and carbon emissions. Fortunately, the plate and tube laser cutting machine is a technology that naturally supports sustainability in industrial workflows.

Traditional cutting methods, such as mechanical shearing, sawing, or plasma cutting, often produce excess scrap, offcuts, and dust. These byproducts not only increase material costs but also lead to higher disposal and cleanup expenses. In contrast, laser cutting provides high-precision output, which significantly reduces raw material wastage. Since every cut is programmed and digitally optimized, manufacturers can nest parts closely together, extracting more usable product from each sheet or tube.

The UAE’s shift toward sustainable manufacturing also encourages energy efficient equipment. Most modern plate and tube laser cutting machine is powered by fiber laser cutting technology, which consumes less power than older CO2 systems while delivering faster cuts. This translates to lower electricity bills, especially for facilities running multiple shifts. Another overlooked benefit is reduced reliance on consumables. With no need for blades, mechanical dies, or abrasive media, the operational footprint of a laser cutter is considerably smaller. Fewer consumables mean fewer supply chain dependencies and lower carbon emissions from shipping and packaging materials.

For companies pursuing environmental, social, and governance goals or aiming for ISO 14001 environmental certification, the integration of a plate and tube laser cutting machine can help demonstrate commitment to eco conscious practices. It aligns with the UAE’s national initiatives toward green industry development and responsible resource use.

Moreover, sustainability isn’t only about being green, it’s also about long term business survival. Minimizing waste and maximizing material yield allows companies to stay cost-competitive, especially when dealing with fluctuating metal prices or import tariffs. With this machine in their workflow, UAE based manufacturers aren’t just saving material, they’re building smarter, more sustainable operations.

Resilient Manufacturing with Plate and Tube Laser Cutting Machine

Global supply chain disruptions have made one thing clear: manufacturers need more control. Investing in a plate and tube laser cutting machine empowers UAE based businesses to bring critical operations in-house, reducing dependency on external suppliers. Instead of waiting on delayed imports or third party cuts, companies can produce both flat and tubular components on demand. This ensures faster turnarounds, tighter quality control, and fewer bottlenecks, even during global material shortages.

In-house laser cutting also enables just in time production, minimizing excess inventory while supporting fast design changes. Whether serving urgent contracts or custom orders, manufacturers can respond swiftly without compromising on quality. For small to mid-sized companies in the UAE, this level of self reliance offers a strategic edge. It not only lowers operational risks but also strengthens client trust by ensuring delivery continuity. Ultimately, the plate and tube laser cutting machine transforms manufacturing from reactive to proactive, keeping businesses agile, efficient, and future ready.

Precision and Customization with Plate and Tube Laser Cutting Machine

In today’s fast paced UAE manufacturing sector, delivering precision and customization is vital. The plate and tube laser cutting machine offers both, making it a key asset for businesses seeking a competitive edge. With laser technology, manufacturers can achieve clean, accurate cuts across a range of materials. There’s no need for rework or secondary processing. This not only improves product quality but also saves valuable time.

Customization is equally simple. Whether producing detailed signage, structural brackets, or prototype parts, operators can switch designs quickly using digital files. There’s no need for new tooling or lengthy setup. For businesses handling diverse client needs, this flexibility is a major advantage. From one off jobs to high volume runs, the same machine adapts with ease. Delivering consistent results and faster turnaround. Ultimately, the plate and tube laser cutting machine empowers UAE manufacturers to meet modern demands with speed, accuracy, and tailored solutions. That keeping them one step ahead of the competition.

SGI Dubai Success Story Highlights Business Point International, UAE

The SGI Dubai exhibition proved to be a remarkable success with Business Point International, UAE emerging as a standout participant. Showcasing a wide range of advanced digital printing machines including UV printers, roll to roll printers, flatbed UV printers, hybrid UV printers, solvent printers, eco solvent printers and sublimation printers. It attracted strong attention from industry professionals. Business Point International’s presence underscored its growing reputation as a leading supplier of industrial machinery in the UAE. This success story strengthens the company’s role in driving innovation and excellence in the printing sector.

Also, Check Out Our SGI Dubai Event Highlights Video (2019 – 2024)

SGI Dubai 2019 – Showcasing our latest digital printing machines at SGI Dubai. Watch the highlights: [https://youtu.be/RZnjD9cW9WE] [https://youtu.be/MVXMp17whGU]

SGI Dubai 2020 – The future of digital printing machines unfolds at SGI Dubai. See the event videos : [https://youtu.be/SHPgbfXk25s] [https://youtu.be/0ltRPVyB72w]

SGI Dubai 2023 – Bringing together industry leaders and advanced digital printing machines at SGI Dubai. Experience it here: [https://youtu.be/UWIoG61WJgk]

SGI Dubai 2024 – A stage to present modernized digital printing machines. Check out our event highlights: [https://youtu.be/94gKmneM6cE]

Conclusion

Investing in a plate and tube laser cutting machine is a strategic move for manufacturers looking to enhance precision, streamline operations, and stay ahead in a competitive UAE market. These machines go beyond traditional tools by offering advanced cutting capabilities, fast turnaround, and high customization. And making them ideal for both large industries and agile SMEs. From boosting supply chain resilience to supporting Industry 4.0 integration, they provide a future ready foundation for smart manufacturing.

At Business Point International, we offer top tier Plate and tube laser cutting machine built for durability, speed, and accuracy. Based in the UAE, we deliver not just machines but complete end to end support, including expert advice, installation, and after sales service. Whether you’re cutting flat metal sheets or complex tubular frames, our solutions are tailored to meet your exact production needs. Contact Business Point International today to discover how our cutting edge laser technology can help you scale, optimize, and lead in a rapidly evolving industrial landscape.