Fiber laser tube cutting machine is revolutionizing the way different industries approach the cutting and shaping of material. It is a highly developed technology for cutting metal tubes and pipes with the aid of a high-power laser beam. In manufacturing work, that machinery is very vital since it contributes to efficiency, accuracy and cutting down on wastage. Fiber laser tube cutting machines have significant functions regarding the types of materials and the thickness they can cut which makes it an efficient tool in current production needs. This blog will introduce the foundational knowledge regarding these machines, the advantages that they have and the changes they bring across various sectors. First, second and third sources of information will also be used as additional sources of information on the current success stories of the fiber laser cutting technology and future prospects. Welcome to a new and exciting piece where we will explore the field of fiber laser tube cutting machines and their significance.

General Overview of Fiber Laser Cutting Machines

High-definition fiber laser cutting machines have gone a long way in changing the ways in which various materials are cut. These machines incorporate the utilization of optical fiber to create a high-power laser beam aimed at cutting metals with high precision. Laser cutting is very precise and the beam is very narrow, thus resulting in a high output with slender kerf. Fiber laser cutting is becoming widely known as one of the better ways to cut through various materials, and fiber laser cutting machines come in various forms and designs.

High-definition fiber laser cutting machines have gone a long way in changing the ways in which various materials are cut. These machines incorporate the utilization of optical fiber to create a high-power laser beam aimed at cutting metals with high precision. Laser cutting is very precise and the beam is very narrow, thus resulting in a high output with slender kerf. Fiber laser cutting is becoming widely known as one of the better ways to cut through various materials, and fiber laser cutting machines come in various forms and designs.

Different Types of Fiber Laser Cutting Machines

Fiber Laser Tube Cutting Machine: These machines are made specifically for cutting metals of tubes and pipes commonly used in industries. It is noted that their strength is particularly in the detailed shape and patterns and therefore suitable for industries where metalwork is particularly complex such as the automotive and aerospace industries.

Fiber Laser Cutting Machine: They are applied on flat metal sheet products. This offers high accuracy and glamorous speed that can be adopted widely in producing various parts in electronics, automobile and machinery businesses.

Fiber Laser Engraving Machine: These are utilized for counterstaining and cutting metal. These dials are popular in the jewelry, medical and electronics industries to include intricate branding and engravings.

Use Cases of Fiber Laser Cutting Machines

Automotive Industry: The fiber laser tube cutting machines are used to produce cut parts including the exhaust pipes and other structural parts. They increase manufacturing productivity and guarantee that the yields are of top-notch standard.

Aerospace Industry: These machines are used in cutting lightweight and strong materials for the production of aircraft. Their precision is important when value is to be provided to aerospace equipment that requires high standards of safety and efficiency.

Construction and Architecture: Fiber laser cutting machines in flatbed form create personalized metal panels and frameworks. They help architects and builders to accomplish fancy designs and at the same time guarantee the stability of structures.

Medical Device Manufacturing: Fiber laser marking and cutting machine engraves and cuts parts and components for medical devices. They provide very high accuracy and reproducibility, features which are crucial in the medical field.

Furniture and Home Appliances: With such machines, designers can be able to etch sophisticated patterns on metallic furniture as well as the apartment parts considered decorative and useful.

A fiber laser cutting machine may be described as a cutting machine that is being used in various fields and industries. Of them, they are precise, fast, and can work on a variety of materials making them very useful in current production.

Enhancing Expertise with Fiber Laser Cutting Machines

Evaluating the subject matter includes outlining the pros of fiber laser cutting machines and the extension of their importance in various industries adds to the depth of knowledge acquired.

Technical Advantages of Fiber Laser Cutting Machines

Precision and Accuracy: Fiber lasers provide a very high density of light and thus excellent accuracy of the incisions that are to be made. Such precision minimizes wastage of material and creates uniformity, factors that are very important, especially for applications of laser cutting machine such as aerospace or the manufacture of medical appliances.

Speed and Efficiency: These machines work at enormously high speeds and this results in short cutting times. High speed is another advantage which means that the manufacturing rate is also high as a way of trying to meet the asked demand in the market within a short period of time while still maintaining high-quality production.

Versatility: Fiber laser cutting machine is capable of cutting through materials such as stainless steel cutting machine, aluminum brass, copper and many others. They can also accommodate varying thicknesses of the material, thereby being appropriate for various uses in many sectors.

Low Maintenance: The fiber laser is also noted to have few components hence the name solid state lasers. This ultimately leads to reduced maintenance and a longer life span for the machines, thus cutting down costs of downtime.

Industry Impact and Use Cases

Automotive Industry: Manufacturers employ the tube laser cutting machine in producing complicated exhaust systems, chassis parts as well as structural frameworks. The cutting with a high level of precision also guarantees that all the assembled components are well-fitted hence enhancing the efficiency, and safety of the entire vehicle.

Aerospace Industry: This is why accuracy is critical when using fiber laser cutting machines to cut lightweight and superior materials such as that used in aircraft construction. They aid in the production of component parts that possess strict requirements for safety and performance resulting in the dependability and viability of present day flying machines.

Medical Device Manufacturing: Fiber laser cutting and engraving machines are used for generating complicated and high-quality parts for use in the medical gadgets industry. Whether in producing body implants or designing and manufacturing thin flexible screens, nothing beats the accuracy and cleanliness of laser cuts for overhauled medical equipment.

Construction and Architecture: Fiber laser cutting machines in construction are used to make tailored metal structures, ostentatious items, and application parts. The application of 3D printing in construction is advantageous to architects and builders through the making of perfect model solutions that serve functions and appearance.

Furniture and Home Appliances: Such machines enable the production of designs on metal furniture and appliance parts with utmost precision. The outcome is a higher production quality, especially when it comes to aesthetics and the product’s long-term resilience.

Future Trends and Innovations in Fiber Laser Cutting Technology

The future of fiber laser cutting technology is promising, with ongoing advancements and innovations:

Integration with Automation and AI: Recently, advanced technologies have continued to incorporate fiber laser cutting machines with automation and artificial intelligence. It enhances cutting accuracy, optimizes the manufacturing process, and decreases human interference influence.

Hybrid Machines: The refinement of the laser cutting machines via integration with other processes like additive manufacturing or 3D printing also offers new possibilities and uses.

Sustainability: There are prospects in increasing energy efficiency, thereby improving upon the devices to reduce their impact on the environment, which is today’s common trend.

Understanding Fiber Laser Tube Cutting Machines

Definition and Basic Working Principle

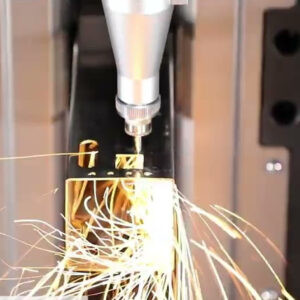

A fiber laser tube cutting machine implements the application of laser cutting in cutting metal tubes and pipes in a very accurate manner. Light from a fiber laser is used to irradiate the material where the formation of a small, intensive area of the laser beam takes place. This concentrated light warms up the material to the level that it softens and can be either cut away with ease or evaporated. The laser or the tube is rearranged to cut the material in the predefined pattern and the whole process is computer controlled for accuracy.

Key Components and Technology

Laser Source: The fiber laser produces the high-power beam used in cutting. This laser is energy-sufficient and does not compromise on the performance.

Cutting Head: The Laser cutting head directs the laser beam on the material that is to be cut. It sometimes consists of a nozzle for delivering assist gas, although this can be nitrogen or oxygen, to help sweep away the melted material and provide a clean kerf.

CNC Cutting Machine System: Computer numerical control for the laser and for the material that is being worked on to determine its movement. It gives accuracy and controllability, which are imperative to repeat similar patterns and shapes needed in the creation of intricate frosting designs.

Support Structure: This embraces the bedding or fixture that supports the tube. The structures present in some machines include mechanisms that automatically turn and orient the tube to cut the various portions.

Comparison With Traditional Cutting Methods

Fiber laser tube cutting machines offer several advantages over traditional cutting methods like mechanical sawing, plasma cutting and water jet cutting.

Precision and Accuracy: Fiber lasers are very accurate in cutting and the kerf or the thickness of the cut is slim, meaning there are very minimal wastes and the components fit well when placed together.

Speed and Efficiency: Basically, laser cutting is far more efficient than the conventional techniques in cutting metals. It can help speed up the cutting of materials which usually helps in raising production rates and decreasing lead time.

Versatility: These machines can suit a wide range of thicknesses as well as the type of material that is to be cut. Common techniques can be ineffective with particular metals or need one apparatus for another material.

Low Maintenance: The fiber lasers have fewer features of mechanical movement and vibration; thereby, they have less or no problem with maintenance as compared to mechanical cutters; thus their operational cost and time are significantly fair.

Fiber Laser Tube Cutting Machine Applications in Various Industries

Fiber laser tube cutting machines are fast revolutionizing a vast of industries since they are precise, efficient and flexible. We should look into how various industries are employing it and what they output in terms of content in real time.

Automotive Industry

In the field of automotive industry, fiber laser tube cutting machines are indispensable in the fabrication of numerous parts. For instance, these machines are utilized in producing exhaust systems that give a correct fit and efficiency due to clean-cutting techniques necessary for the application. They also do the cutting of intricate profiles for other mechanical components, for instance, the frames and rollover hoops that improve the stability and sturdiness of vehicles.

Example: Laser tube cutters are used by car manufacturers to produce slender components for fast sports utility vehicles. In this way, they increase reasonable accuracy of production and make great contributions to minimizing material losses, hence achieving better quality and eliminating waste in production.

Aerospace Industry

The aerospace industry is very particular about the accuracy and reliability it expects from a product, fiber laser tube cutting machines fit the bill. These machines shave parts that are light and strong to support the structure of aircraft like the frames and brackets. By analyzing the accuracy control of fiber lasers, the part is safe and performs as the standard requires.

Example: Automobile manufacturers employ fiber laser tube cutting machines in the building of spare parts, which are of perfect fit within the structures of airplanes. The mentioned precision is useful for decreasing the aircraft’s weight, which further has a positive impact on the fuel consumption and the overall performance of the plane.

Construction and Architecture

In construction and architecture, fiber laser tube cutting machines are applied in fabricating the required metal structures, fences and other structures, and designs. They enable the creation of designs that favor the architecture and aesthetics of the edifices to be constructed.

Example: In architectural firms, fiber laser tube cutting machines are used in the architectural designs and the construction of facades and metal structures. Due to this capability, architectural creativity and innovative methods while developing building designs can be enhanced, at the same time improving construction reliability.

Medical Device Manufacturing

The medical devices industry can most certainly vouch for how helpful the fiber laser tube cutting machines are due to their precision. These machines are employed to produce parts of medical instruments and tools, implants and any related devices that would require precision to the highest degree.

Example: Manufacturers in the production of stents as small tube-shaped devices that are installed to keep the blood vessels open rely on fiber laser tube cutting machines. The particular cuttings that the factories apply guarantee the stents have adhered to set medical requirements in order to help the patient and be effective.

Furniture and Home Appliances

In furniture and home appliances for instance fiber laser tube cutting machines can be used to make sharp erosions with good aesthetics. Fluent in the use of machines that customize metal parts used in furniture frames, lighting and kitchen appliances that are fashionable as well as functional.

Example: Some of the products that industries apply fiber laser tube cutting machines include metal frames for the chairs and tables used in manufacturing furniture. It makes it possible to achieve creative and functional structures for products that meet modern consumers’ expectations in terms of aesthetics and durability.

Conclusion

Transform your manufacturing capabilities with precision driven technology. Fiber laser tube cutting machine. Business Point International of UAE is a market leader in innovative solutions to provide high-quality work that creates new milestones in regional standards. The seriousness of Sears in providing nothing but only the best comes out clearly when it comes to our superior fiber laser cutting technology.

In automotive manufacturing, aerospace components, building construction, medical device production, furniture production, our spectrum of fiber laser machines has it covered. Business Point International ensures our products and services in a way that is effective and at the same time cuts costs so that the clients get improved productivity. They allow for fast production cycles and a great variety of designs so you can encourage your business success in aggressive environments.

Consider today’s capabilities that are associated with fiber laser technology. Reach Business Point International, UAE and learn more about how we can improve your manufacturing line.