The fiber laser cutting machine stands as a revolutionary material processing industry, propelling businesses towards unparalleled precision for the output. At Business Point International, situated in the vibrant hub of innovation, the UAE. We take pride in being the premier supplier of cutting-edge fiber laser cutters. In this comprehensive guide, we delve into the intricate world of fiber laser technology that assists in navigating through the selection process, understanding the working principles and exploring its myriad applications.

The Outline,

● How to choose a suitable fiber laser cutting machine?

● What is the working principle of a fiber laser cutting machine?

● Can a fiber laser cutting machine effectively cut metals?

● How to choose the right power for the industry?

● How to maintain the machine properly?

● What are the advantages for the industry?

● What are the applications of the industry?

Choosing the Perfect Fit

Investing in a fiber laser cutting machine is a pivotal decision for businesses, acts as an informed choice. Consider factors such as power requirements, cutting speed, laser power and material versatility. We are offering a diverse range of machines tailored to fulfill the unique industrial demands of the operations. Our expert team of engineers assist in evaluating the specific needs and ensure that the chosen machine seamlessly integrates into the workflow.

Unveiling the Working Principle

The fiber laser cutting machine has a meticulously engineered system, utilizing high-powered laser beams generated through fiber optics and achieves unprecedented precision. Our cutting-edge fiber laser technology employs a combination of active components, ensuring consistent and reliable performance. Dive into the world of modernization and demystify the science behind the magic of material processing.

A Cut Above: Can Effectively Cut Metals?

Absolutely. It is highly extending beyond conventional boundaries. It is specifically designed to tackle a wide range of metals such as stainless steel, carbon steel, copper, aluminum, nickel, manganese & other metal types with unmatched precision. Our machines at Business Point International guarantee pristine cuts that give a competitive edge in the market.

Precision Redefined

It is operating with unparalleled speeds, significantly reducing operational time and boosting overall efficiency. Assists in achieving sharp accuracy with minimal kerf width and ensures each cut meets the highest standards of precision.

Versatility in Material Handling

Processing of thin sheets to thick plates handles a diverse range of materials and is crucial for various industries. It has a low operating cost with minimal maintenance requirements and energy-efficient production. Contributes to a cost-effective production environment.

Applications Beyond Imagination

Fiber laser technology transcends traditional limitations, finds applications across various industries. This machine empowers the business with the flexibility to cut intricate designs and shapes. Witness the transformative impact of the equipment on the manufacturing processes.

Choosing the Right Wattage for The Machine

Selecting the appropriate laser power level is a critical aspect of optimizing the processing performance. At Business Point International, our range spans from lower wattages suitable for thin materials to higher wattages for thick from 3 kW to 40 kW. Our team of experts guides the decision-making process and ensures the chosen machine aligns seamlessly with your production requirements.

Maintaining Excellence

To preserve the longevity performance of the machine demands a proactive approach to maintenance. Regular checks on optics, beam delivery systems and cooling mechanisms are imperative. Our dedicated support team provides comprehensive maintenance guidelines and operates at peak efficiency throughout its lifecycle. We are taking pride in bringing cutting-edge fiber laser technology to your doorstep. Elevating the manufacturing capabilities, embracing precision and staying ahead in the industry. Make the innovative journey and excellence in metal fabrication.

This comprehensive guide aims to provide valuable insights into choosing and optimizing the performance for effective production.

Choosing a Suitable Fiber Laser Cutter

● Understanding Your Requirements

Before delving into the selection process, it is crucial to assess your specific requirements. Also, consider factors such as the type of materials, laser power, speed efficiency, the type of materials working with, thickness requirements, production volume and budget constraints. It is utilizing fiber optics to deliver the laser beam and chooses a machine with a reputable laser source based on the cutting needs.

● Cutting Area and Bed Size

Evaluate the size of the cutting area and bed size which assists in accommodating the dimensions of the workpieces. The highly optimal space utilization can enhance productivity

● Automation Features

The advanced automation features of the machine like CNC controls, automatic nozzle changers and material handling systems. It also has the features to improve efficiency and reduce manual labor.

● Cooling System

Efficient cooling is important for maintaining laser performance and protects the material from distortion. Choose a machine with a reliable cooling system for stable operation which ensures output consistently.

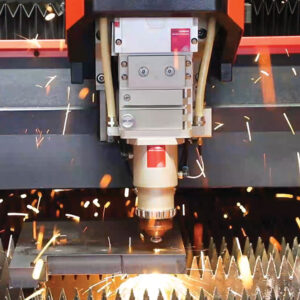

● Laser Generation

It generates the laser beam through the process of stimulated emission within an optical fiber. Gets the results in a highly concentrated and coherent beam of light. The laser beam delivers the flexible optic cable, allowing for precise and agile movement. These advanced features enhance the machine’s accuracy and speed. The laser beam interacts with the material to create a high-intensity heat zone. Then, the material absorbs the energy, leading to rapid heating, melting and ultimately, cutting the material for the output.

● Effectively Cutting Metals

The machine excels in cutting a wide range of metals including stainless steel, aluminum, copper and more. The versatility makes it suitable for various industries from automotive to aerospace.

● Thickness Capabilities

The focused high-energy laser beam ensures fast processing, ideal for intricate designs and high-volume production. It can effectively cut thin & thick materials, powers are measured in kilowatts which plays a crucial role in determining its thickness-cutting capabilities.

Here’s a table summarizing the components, respective uses in the overall functionality and their usage in a fiber laser cutting machine:

| Component | Usage |

|---|---|

| Laser Source | Generates high-powered laser beams through fiber optics for material cutting. |

| Fiber Optic Cable | Transmits the laser beam with flexibility and precision to the cutting head. |

| Cutting Head | Focuses and directs the laser beam onto the material for cutting. |

| Working Table | Provides a stable surface for the material being cut and assists in optimal space utilization. |

| Guide Rail | Guides the movement of the cutting head, ensuring precision and accuracy in the cutting process. |

| CNC Controls | Enables automation, controlling the movement and operation of the cutting machine. |

| Automatic Nozzle Changer | Automates the changing of nozzles, reducing manual labor and improving efficiency. |

| Material Handling System | Automates the feeding and removal of materials, enhancing efficiency in production. |

| Cooling System | Maintains laser performance and prevents material distortion by efficiently cooling the machine during operation. |

| Lubrication System | Ensures proper lubrication of moving parts to prevent friction and maintain smooth operation. |

| Advanced Monitoring System | Monitors and controls the cutting process, detecting and correcting deviations or errors for high-quality output. |

| Quality Control Features | Contributes to maintaining high-quality products by ensuring precision and adherence to standards and regulations. |

Advantages of Fiber Laser Cutting Machine

● High Precision

This machine offers unparalleled precision and allows for intricate designs with fine details. It is suitable for applications where precision is non-negotiable.

● Efficiency

The speed of fiber lasers is significantly higher than traditional cutting methods, leading to effectively higher productivity. High cutting speeds assist for shorter production cycles with faster turnaround times.

● Low Maintenance

Compared to other cutting technologies, fiber lasers have lower maintenance machinery requirements. The absence of mirrors in the laser path efficiently reduces the need for frequent parameter adjustments and component replacements.

● Energy Efficiency

The fiber laser is more energy-efficient than CO2 lasers. Contributes to reduced power consumption and operational costs.

● Minimal Downtime

With fewer components, the machine experiences minimal downtime. Reliability is important for meeting production deadlines and maintaining consistent output.

Applications of Fiber Laser Cutting Machine

● Automotive Industry

It is extensively used in the automotive sector for cutting various components including chassis parts, body panels and exhaust systems. The precision of the laser delivers efficient manufacturing processes.

● Aerospace and Defense

In the aerospace industries, where detail accuracy is paramount, employed for manufacturing intricate components such as turbine blades, aircraft parts and military equipment.

● Metal Fabrication

The fiber laser is widely used in metal fabrication for cutting and shaping sheet metal, tubes and profiles. It is versatile equipment that has the capability to handle various thicknesses and materials.

● Electronics and Electrical

The minimal heat-affected zone of the fiber laser makes it suitable for cutting and marking electronic components such as circuit boards and electrical enclosures.

● Medical Device Manufacturing

It has a vital role in the production of medical devices, including surgical instruments and implant components. The precision ensures the creation of intricate and accurate medical components.

Choosing the Right Power

● Material Thickness

The power of the machine is the critical factor in determining the processing capabilities. Consider the thickness of the materials that the industry frequently works with and choose equipment with sufficient power for optimal performance.

● High-Power Applications

To cut thicker materials or for high-volume production, opt for the high-power fiber laser machine. Machines with power exceeding 6 kW are suitable for heavy-duty applications.

● Low-Power Applications

If the processing needs involve thinner materials or intricate designs, a lower power of around 3 kW is more suitable. It provides more cost-effectiveness for lighter applications.

How to Maintain The Machinery

● Regular Inspection

Perform routine visual inspections that identify any damage or misalignment. Check the condition of the laser source, fiber optic cable, working table, guide rail, laser head and other critical components.

● Cleaning

Keep the machine clean, preventing the debris and dust that affects the performance. Regularly clean the lens, mirrors, cutting table and laser head. Ensure that the working bed remains free of accumulated material.

● Lubrication

Proper lubrication of the moving parts is essential to prevent the friction. Follow the supplier’s recommendations for lubrication intervals and use the recommended lubricants for better processing.

● Calibration

Regularly calibrate to maintain the accuracy of the design. Check and adjust the laser focus, material alignment and beam quality according to the specifications.

● Cooling System Maintenance

Monitor the cooling system that operates efficiently and won’t damage the output. Cleaning or replacing filters, checking for any signs of coolant leakage and maintaining optimal cooling are crucial for laser performance.

● Software Updates

Keep the equipment’s software up to date by installing the latest updates for the advanced features provided by the manufacturer. It ensures compatibility with new materials and technologies.

● Operator Training

Provide thorough training for the operators, to understand proper operating procedures, safety protocols and routine maintenance tasks. Well-trained operators contribute to the longevity of the machine.

● Quality Control

Advanced monitoring systems and quality control features are capable of detecting and correcting any deviations or errors during the cutting process. Ensures high-quality goods, ability to monitor & trace each cut gives essential data and simplifies compliance with standards & regulations.

Wrapping Up

In conclusion, investing in a fiber laser cutting machine requires careful consideration of specific requirements, understanding the working principles, effective productivity of manufacturing operations, capacity to handle complicated designs and implementing effective maintenance practices. It develops a good reputation, attracts more customers, boosts profitability by providing high-quality products and maintaining the machine diligently. Unlock a new era of efficiency and accuracy in metal cutting processes. Business Point International, UAE is the best supplier of industrial machinery for various metal cutting.