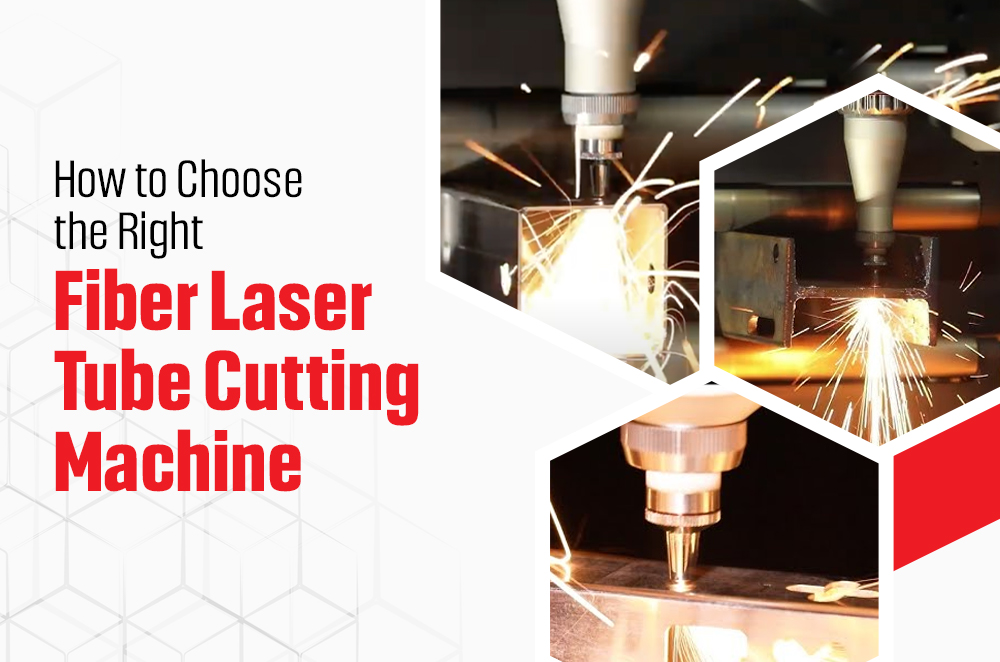

Cutting metal tubes might sound straightforward, but in industries like automotive, construction, and furniture, even the smallest mistake can lead to big problems. That’s where a fiber laser tube cutting machine comes in. This advanced tool uses laser technology to make quick, clean, and precise cuts, helping businesses save time and reduce waste. In this blog, we’ll break down what a fiber laser tube cutting machine is, how it works, and why it’s becoming a go-to choice for manufacturers. Whether you’re looking to improve your production process or just curious about the technology, this guide will give you all the answers you need.

What is a Fiber Laser Tube Cutting Machine?

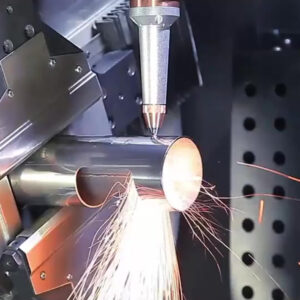

A fiber laser tube cutting machine is a specialized tool designed to cut metal tubes and pipes with high precision. It uses a focused fiber laser beam to slice through metals, offering clean and accurate cuts even on complex shapes and designs. Unlike traditional cutting methods, this machine operates with minimal manual intervention, providing automated and efficient solutions for industries that require high-quality metal components.

A fiber laser tube cutting machine is a specialized tool designed to cut metal tubes and pipes with high precision. It uses a focused fiber laser beam to slice through metals, offering clean and accurate cuts even on complex shapes and designs. Unlike traditional cutting methods, this machine operates with minimal manual intervention, providing automated and efficient solutions for industries that require high-quality metal components.

The machine is ideal for cutting a wide range of materials, including stainless steel, carbon steel, aluminum, brass, and other metals. Its advanced technology not only improves cutting speed but also enhances productivity by reducing the need for secondary processing like grinding or finishing. Modern fiber laser tube cutting machines are equipped with features like automatic material loading, real time monitoring, and software integration for precise control. These features make it a perfect fit for industries such as automotive, construction, furniture manufacturing, and more, where precision and efficiency are critical.

Innovative Features of a Fiber Laser Tube Cutting Machine

Modern fiber laser tube cutting machines are packed with innovative features that set them apart from traditional cutting methods. These features not only improve efficiency but also enhance precision and versatility in various manufacturing applications.

Automatic Calibration: The machine automatically adjusts the laser head according to the material’s size and thickness, reducing setup time and minimizing human error.

High Speed Cutting with Precision: Equipped with advanced laser technology, the machine offers high speed cutting without compromising accuracy, ensuring clean and smooth edges on metal tubes.

Smart Software Integration: Many machines support CAD/CAM integration, allowing operators to input complex designs directly into the system. This feature enables precise cuts and supports creative manufacturing solutions.

Multi-Angle Cutting Capabilities: With rotary chucks and 3D cutting options, the machine can handle cuts at various angles, making it ideal for creating complex structures and designs.

Automated Loading and Unloading: The automation of material handling processes boosts productivity and reduces labor costs, streamlining the entire production line.

Energy Efficiency: The fiber laser source is known for its low power consumption, providing an eco-friendly and cost-effective solution for metal tube processing.

Enhanced Safety Features: Built-in sensors and safety systems help prevent accidents, ensuring a safer work environment for operators.

Maximizing Efficiency with Fiber Laser Tube Cutting Machines

A fiber laser tube cutting machine is not just about precise cuts, It’s a game changer in boosting operational efficiency across manufacturing floors. The machine’s advanced technology streamlines processes, allowing businesses to meet tight deadlines without sacrificing quality.

1. Faster Production Cycles

The high-speed laser cutting capability significantly reduces the time needed for each cut. When combined with automated loading and unloading features, manufacturers can handle large scale orders swiftly, maximizing throughput.

2. Reduced Material Waste

The laser’s pinpoint accuracy ensures cuts are made exactly as designed, minimizing scrap material. The optimized nesting software helps position designs efficiently on metal sheets, utilizing every inch of the raw material.

3. Streamlined Workflow

The machine integrates seamlessly with digital design tools, enabling a smooth transition from concept to production. This integration reduces the manual steps involved, speeding up the entire manufacturing process.

4. Consistent Quality Output

Unlike manual cutting methods that may vary with human performance, the fiber laser tube cutting machine offers uniform quality. Whether it’s the first piece or the thousandth, the cut remains precise and clean.

5. Labor Cost Optimization

Automation can reduce the dependency on manual work of labor for repetitive tasks. Employees can focus on more complex aspects of production, contributing to business growth and innovation.

6. Maintenance that Boosts Productivity

The machine’s low-maintenance design means fewer interruptions in production. Scheduled maintenance is quick and straightforward, ensuring maximum uptime and reliability.

Cost and Investment Considerations for Fiber Laser Tube Cutting Machines

Investing in a fiber laser tube cutting machine is a significant decision for any business. While the initial cost might seem high, understanding the broader financial impact can help businesses make informed choices:

Initial Investment: These machines vary widely in price depending on the brand, features, and automation level. High end models with advanced features typically cost more but offer enhanced productivity.

Long-Term Savings: The precision of fiber laser cutting minimizes material waste, directly reducing costs. Additionally, faster production cycles lower labor expenses and improve profitability.

Operational Costs: Fiber lasers are known for their energy efficiency, which translates to lower electricity bills compared to traditional cutting methods.

Maintenance Costs: These machines have fewer consumable parts and require less frequent maintenance, further saving costs over time.

Return on Investment: Many businesses see ROI within a few months to a year, especially when replacing older, less efficient equipment.

How Fiber Laser Tube Cutting Machine Improve Production Workflows

The fiber laser tube cutting machine isn’t just about precise cuts. It’s a transformative tool for optimizing production workflows. From reducing manual labor to enhancing safety, these machines offer a holistic approach to improving operational efficiency.

1. Automation and Workflow Efficiency

Modern fiber laser tube cutting machines integrate seamlessly with automated systems, enabling continuous production with minimal human intervention. Automation reduces errors, speeds up repetitive tasks, and frees up staff for more strategic roles.

2. Precision and Consistency

One of the standout benefits is the machine’s ability to produce identical cuts every time. This consistency ensures uniformity in products, which is critical in industries like automotive and aerospace, where precision is non-negotiable.

3. Material Utilization and Waste Reduction

With advanced software and nesting capabilities, these machines maximize material usage. By optimizing how cuts are arranged on metal sheets, businesses can reduce waste and save costs on raw materials.

4. Enhanced Safety Measures

Traditional cutting methods often involve manual handling, which increases the risk of accidents. Fiber laser technology reduces the need for direct human contact, enhancing workplace safety and minimizing injury risks.

5. Versatility in Material Handling

The machine can handle a variety of materials from steel and aluminum. And more delicate metals without compromising on quality. This versatility allows businesses to diversify their product offerings and meet varied client demands.

6. Integration with Digital Manufacturing

Many of these machines are equipped with smart technologies that allow integration with digital design software. This capability supports Industry 4.0 initiatives, offering data-driven insights into production processes and allowing for predictive maintenance.

Choosing the Right Fiber Laser Tube Cutting Machine: Expert Tips for Buyers

When purchasing a fiber laser tube cutting machine, it’s essential to choose a model that not only meets your immediate needs but also supports your business’s growth. As a trusted supplier, we at Business Point International understand that making the right choice involves more than just comparing specs. It’s about aligning the machine with your operational goals and budget.

1. What Are Your Production Requirements?

Start by identifying your production needs. Are you handling high-volume manufacturing or bespoke projects? For heavy-duty, large scale operations, consider machines with higher power ratings and automation features. For smaller batches or custom designs, a model with versatility and precision might be more suitable.

2. Which Materials and Thicknesses Will You Be Cutting?

Different machines handle different materials and tube thicknesses. Our range includes models suitable for a variety of metals and thicknesses, ensuring you find the perfect match for your industry. Whether it’s automotive, construction, or metal fabrication.

3. How Much Space Do You Have?

Before purchasing, measure your workspace. We offer compact models for smaller workshops as well as large-scale machines for industrial environments. Our team can guide you in choosing a machine that fits seamlessly into your existing setup.

4. What Automation Level Suits Your Business?

Machines with higher automation can significantly boost productivity. Features such as automatic loading and unloading, smart software integration, and real-time monitoring are available in our advanced models. However, if your business involves more manual processes, a semi-automatic machine might offer the perfect balance between cost and functionality.

5. What Is Your Budget for Initial and Operational Costs?

Beyond the purchase price, consider long term costs, including maintenance, spare parts, and power consumption. We provide transparent cost breakdowns and can suggest models that deliver high ROI through durability and efficiency.

6. How Important Is After Sales Support?

A machine is only as good as the support behind it. At Business Point International, we pride ourselves on offering robust after-sales services, including training, maintenance support, and quick spare part availability. This ensures minimal downtime and maximizes your investment’s value.

7. Do You Need Help with Installation and Training?

Our team not only helps with installation but also provides comprehensive training sessions. We make sure your operators are fully equipped to use the machine efficiently and safely, helping you get up to speed quickly.

Business Point International Praises Success of ‘SteelFab 2024’ at Expo Centre Sharjah

“From the various participating exhibitors, Mian Mahmood, Marketing Manager at Business Point International, which has participated in the event over the last 13 years, stated, that during SteelFab 2024, exhibitors showcase different advanced technologies such as fiber laser and tube cutting laser, highlighting that exhibition supports participants in displaying the machinery in the UAE, and other GCC countries.”

Also, Check Out Our SteelFab Event Highlights Video (2019 – 2025)

SteelFab 2019 – Exhibited our metal fabrication machines and high-speed fiber laser cutting machine. Watch the highlights: [https://youtu.be/QWVEXlSJVCc]

SteelFab 2020 – Showcasing advanced fiber laser cutting machine. Check it out: [https://youtu.be/RFrPcK-oNYo]

SteelFab 2022 – A stage for revolutionary metal processing machines and modernized fiber laser cutting machine. Watch here: [https://youtu.be/Uc8AufxYbGI]

SteelFab 2024 – Bringing together metal fabrication industry leaders and technology pioneers. Experience it here: [https://youtu.be/OM5jt_iJzfQ]

SteelFab 2025 – The future of fiber laser cutting machine and metal fabrication unfolds. See the event highlights: [https://youtu.be/JI1rplS7uDI]

Conclusion

Investing in a fiber laser tube cutting machine can transform your manufacturing processes by enhancing precision, boosting efficiency, and reducing operational costs. By understanding the machine’s features, considering your specific production needs, and evaluating cost factors, you can make a well-informed decision that aligns with your business goals.

At Business Point International, we are committed to providing not only high quality machinery but also exceptional after sales support. Our team is here to assist you through every step of your purchase from choosing the right model to installation and training. With our comprehensive range of fiber laser tube cutting machines, you’ll find solutions tailored to industries such as automotive, construction, metal fabrication, and more. Whether you’re looking to upgrade your current machinery or expand your capabilities, we have the expertise and equipment to support your journey. Reach out to us today to explore our products and discover how our fiber laser tube cutting machines can add value to your business operations.