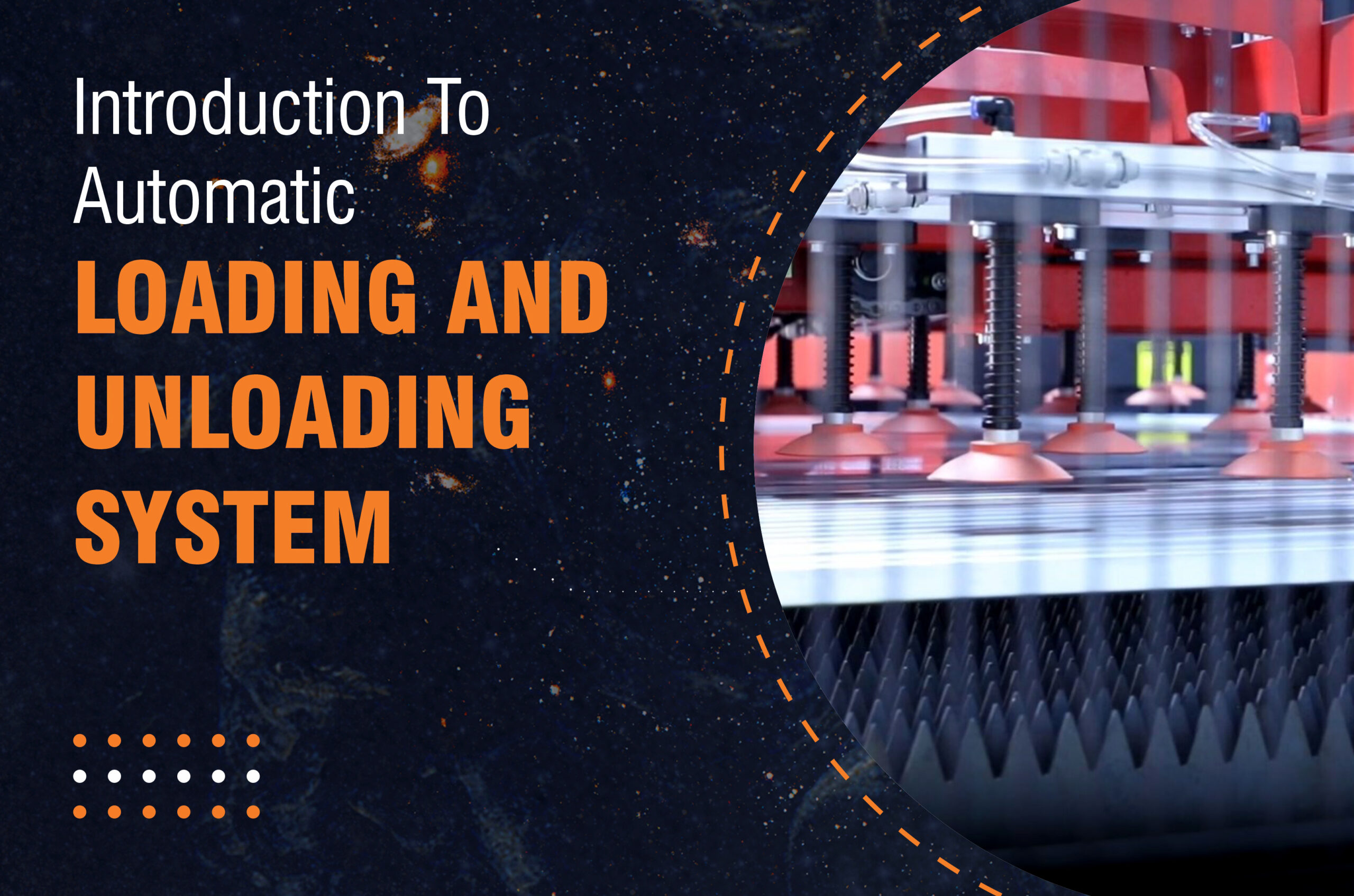

Our modern industrial manufacturing considers efficiency and precision as paramount. Fiber laser cutting machine assists various industries in cutting different metals with high accuracy and speed. Manual handling of materials reduces productivity, increases labor costs and manual handling of materials is not precise. Our automatic loading and unloading system has an advanced mechanism that improves fiber laser cutting operations. It is designed to handle the raw materials and after completion of processing, the output can be removed without human intervention. Provides perfect synchronization with the fiber laser machine with a seamless flow of materials in and out of the machine. It is different from traditional manual processes by automation, achieves high production, avoids human errors in manufacturing and minimizes operational delays.

The automatic material handling system has the ability to optimize the workflow, automate the loading of raw materials such as metal sheets and then transfer the material onto the working table without the involvement of humans. Similarly, the unloading process clears the output product and prepares the system for the next operation which significantly lowers the downtime, allows for continuous operation and improves overall utilization rate with high-volume manufacturing. The benefits of incorporating an automation system are handling heavy metal sheets without any risk for workers, giving safety to the operators and avoiding potential accidents, eliminating accidents and creating a safer workplace with industrial safety standards.

The automatic material handling system has the ability to optimize the workflow, automate the loading of raw materials such as metal sheets and then transfer the material onto the working table without the involvement of humans. Similarly, the unloading process clears the output product and prepares the system for the next operation which significantly lowers the downtime, allows for continuous operation and improves overall utilization rate with high-volume manufacturing. The benefits of incorporating an automation system are handling heavy metal sheets without any risk for workers, giving safety to the operators and avoiding potential accidents, eliminating accidents and creating a safer workplace with industrial safety standards.

Moreover, this system reduces material handling time for the operation, provides precise positioning and avoids material wastage by processing systematically which boosts the overall quality of the end product. It is beneficial for the industrial sectors such as automotive, aerospace, metal fabrication and construction. Also, it has high precision, scalability, is more efficient for manufacturing and makes the units for automated production. Cost-efficient to meet the demands of a competitive market and highly strategic modern enabler for operations.

Advantages of Automatic Loading and Unloading System

1. Enhanced Productivity

This automated system has the ability to increase productivity dramatically while minimizing machine downtime between cutting operations. It loads the raw material automatically into the machine bed seamlessly and immediately releases the finished part or scraps. The continuous workflow makes the operations for longer periods, operates the materials in low time periods, has a high production capacity and fulfils the orders faster. Especially the large-scale manufacturing business eliminates the output delay caused by manual intervention. It makes the machine run non-stop, can possibly for unattended operation, continue the operation for regular working and boosts the efficiency.

2. Reduced Labor Costs

If the operation is run by multiple workers, it requires manual loading and unloading of materials which leads to increased labor costs. The automatic system can significantly cut down the relay on manual labor. Also, to handle the heavy metal sheets, material transfer from output to unloading, repetitive tasks and reducing the need for extra manpower that saves labor expenses. It allows operators to concentrate on higher-value tasks, quality control of output and optimizes the production. Reduces the labor dependency and gives substantial cost savings for the manufacturing industry.

3. Improved Safety Standards

Workers may be at serious risk for physical harm and strain while handling large, heavy, or pointy objects by hand. These hazards are eliminated by the automatic loading and unloading system, which completely automates the material handling procedure. Heavy metal sheets are no longer manually lifted, positioned, or removed by employees, making the workplace safer. Modern safety requirements are also followed in the system’s design, which includes automatic controls and safety sensors to avoid mishaps while in use. By improving workplace safety, companies can save possible downtime and expenses related to workplace injuries in addition to protecting their employees.

4. Consistent Accuracy

Even little faults in material placement can result in expensive blunders in sectors like construction, automotive, and aerospace where accuracy is essential. Errors brought on by manual handling are reduced by the automatic loading and unloading system, which guarantees accurate placement of raw materials onto the cutting bed. The technology guarantees uniformity in material loading and unloading by automating the process, which produces more precise cutting outcomes. This degree of accuracy helps firms preserve their reputation and satisfy customers by minimizing material waste and guaranteeing that the finished products match the highest quality requirements.

5. Time and Cost Savings

Automatic loads and initial investments on descending systems may seem to be high, but the long -term benefits provided by it are incomparable. As time goes on, technology pays by reducing the handling period of materials, maximizing the efficiency of machinery, and reducing labor costs itself. In addition, the expansion of production capacity can accept more orders and increase the possibility of income. In addition, the system can minimize the wear of the machine, limit the interaction of the human, and cause errors and damage. With appropriate maintenance, the automatic system can extend the lifespan of the fiber laser cutting equipment, thus maximizing the return on investment.

Components of Automatic Loading and Unloading System

User-Friendly Control Panel

Our well-equipped control panel streamlines the overall processing, allows the workers to input the order simply, monitor the operation and oversee the operation. It promotes the accurate execution of processing, efficient process workflow, so new users can learn the system and minimize manufacturing or operational mistakes & errors. It simplifies complex tasks by using a control panel with enhances productivity.

Automatic Feeding of Raw Materials

Our loading and unloading system manages to handle raw materials automatically and transfers onto the laser exchange table seamlessly without manual intervention. It reduces labor costs, the potential for human mistakes, continuously supplies the raw material, maintaining the production flow and optimizes the usage of fiber laser cutting machine.

Double Sheet Recognition and Metal Sheet Separating Features

Our automated system is designed with double sheet recognition and metal sheet separating features for enhanced precision. This feature prevents the multiple feeding of sheets simultaneously and protects the system from inaccuracies or potential damage to the machine. It accurately detects and separates every individual sheet to maintain the high-quality output of the equipment.

Integrated Safety Features Such as Real-Time Monitoring

The system is addressed through integrated features as it has many advanced features. It has numerous benefits such as real-time monitoring of processes, continuous oversight of operations to avoid malfunctions and prompt interventions to any type of accidents. This proactive approach of automated system safeguards operators, also assures the longevity of the machine and mitigates the risk before escalates.

Heavy-Duty Trolley

A sturdy trolley with a 5000 kg capacity is part of the system and is made to support huge loads. Large quantities of materials and heavy metal sheets can be accommodated by this function, which is very useful in large-scale production settings. The trolley’s sturdy design guarantees dependability and longevity, which promotes effective material handling and raises manufacturing process productivity overall. Fiber laser cutting machines operate better when these capabilities are included into an autonomous loading and unloading system, which improves productivity, safety, and product quality in industrial settings.

Applications of Automatic Loading and Unloading System

1. Automotive Industry

In the automotive industry, accuracy and productivity are essential. The smooth material handling of metal sheets and components for the production of automobile bodies, exhaust systems, and structural elements is guaranteed by the automatic loading and unloading system. Manufacturers can achieve consistent cutting quality, minimize material waste, and fulfill strict production timelines by automating these procedures. The system is perfect for satisfying industrial demands while upholding safety and accuracy standards because it can also handle high volume manufacturing.

2. Aerospace Industry

Advanced technologies are used in the aerospace sector to handle materials like titanium and aluminum that are lightweight yet incredibly robust. By ensuring precise material placement, this technology makes it possible to cut pieces used in fuselages, wings, and other components of aircraft with accuracy. The high level of precision needed for aerospace applications is ensured by the automation, which lowers human error. Furthermore, its safety features and real-time monitoring make it appropriate for handling pricey and delicate materials with little risk.

3. Construction and Infrastructure

This technique is extremely useful for the construction sector, which frequently uses steel sheets and hefty materials. It facilitates the production of structural steel elements like frameworks, panels, and beams. The process is streamlined by the automatic feeding and unloading, and the sturdy trolley, which can support up to 5000 kg, guarantees seamless material handling. For large scale infrastructure projects, this efficiency is crucial for both cost optimization and on-time completion.

4. Metal Fabrication Industry

Making specialized pieces for a range of sectors is known as metal fabrication. From tiny sheets to heavy duty plates, the automatic loading and unloading system maximizes cutting for a variety of materials and thicknesses. Errors are avoided because of its double sheet detection, which guarantees accurate production of components including frames, brackets, and enclosures. In sectors like electronics and energy, this accuracy and efficiency are essential for satisfying the wide range of customer needs.

5. Shipbuilding Industry

Large metal sheets are used in shipbuilding for decks, hulls, and other ship parts. Production is accelerated and accuracy is guaranteed by the system’s capacity to manage large loads and automate the feeding of raw materials. The technology reduces manual handling, which is important when handling big goods because it reduces errors and safety risks. Shipbuilders can better satisfy design specifications and expedite turnaround times for intricate marine projects thanks to this technology.

Conclusion

An innovative way to improve efficiency, precision, and safety in a variety of sectors is the Automatic Loading and Unloading System for fiber laser cutting equipment. Regardless of your industry. Automotive, aerospace, construction, metal fabrication, or shipbuilding, this technology guarantees smooth material handling, minimal human involvement, and unparalleled accuracy. It is an essential tool for contemporary industrial operations because of its cutting edge features, which include a heavy duty trolley, automatic material feeding, double sheet recognition, real time safety monitoring, and an easy to use control panel. This system easily satisfies the requirements of large scale and high capacity industrial processes by handling items weighing up to 5000 kg.

You may cut expenses and increase efficiency by incorporating automation into your business processes. This approach guarantees constant, high quality production while reducing the amount of manual labor and the chance of mistakes. In addition to ensuring a safe working environment for personnel, the sophisticated safety features shield the machinery from potential damage brought on by handling mistakes. In the end, this automated approach provides a competitive advantage, enabling companies to effortlessly fulfill industry requirements and strict deadlines.

The particular difficulties that UAE manufacturers encounter are something that we at Business Point International are aware of. For this reason, we offer you industrial solutions of the highest caliber that are customized to meet your needs. Your operations will run smoothly and efficiently with the addition of our Automatic Loading and Unloading System to your fiber laser cutting equipment.

Why Choose Business Point International?

Dependable Products: We provide cutting edge industrial equipment designed to provide exceptional durability and performance.

Industry Knowledge: We have years of expertise serving a variety of industrial demands in the UAE market.

All Inclusive Support: Our staff is here to help you at every stage, from installation to post purchase maintenance.

Call to Action

Are you prepared to change the way you produce things? In the United Arab Emirates, Business Point International is your reliable partner for high performance industrial solutions. Purchase the Automatic Loading and Unloading System right now to increase operational effectiveness, reduce expenses, and guarantee accurate cuts every time.

To find out more about this cutting edge system, get an estimate, or arrange a meeting with our professionals, get in touch with us right now. You can go to www.bpiae.com. Together, we can use state-of-the-art automation technologies to propel your company forward.