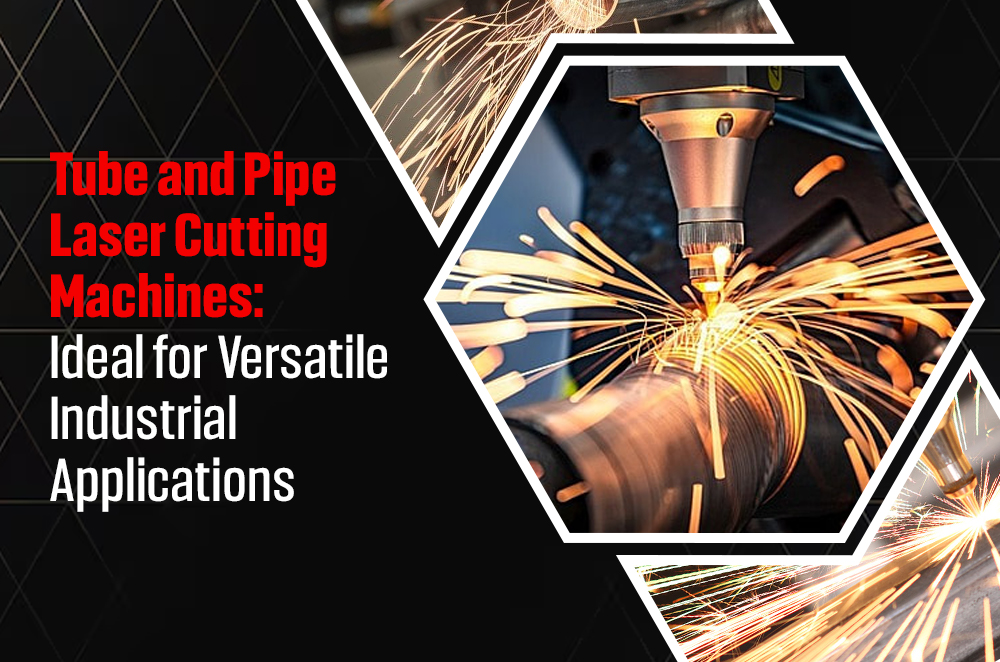

Laser cutting machines especially tube and pipe laser cutting machines are paramount in the present manufacturing processes. Laser cutting and bending machines are employed for cutting and bending tubes and pipes accurately and at greater speeds. This technology is important since it saves time and cuts down on costs in the manufacturing line. Laser cutting machines are commonly implemented in auto manufacturing companies, aerospace industries, construction industries among others because of the precision and quality required. Still, in the subsequent blogs, what the tube and pipe laser cutting machines are, the major characteristics of the machines and the possible advantages that users of the machines are privileged to enjoy shall be discussed in detail. It will also focus on a number of applications and the current market highlights. That is why when comprehending these machines, you find that they are a necessity in manufacturing today. Now let’s go straight into the description of tube and pipe laser cutting machines and peer into the future of industry.

Understanding Tube and Pipe Laser Cutting Machine

Definition and Basic Concept

Tube and pipe laser cutting machines are specific tools for cutting and bending tubes and pipes by means of laser equipment. It also helps in making clean cuts which are important in industries that call for the accuracy of the cuts to be made.

The essentials of these machines include a laser source, cutting head, control mechanism, and a work table/bed on which the material rests. The working principle that is emphasized is the use of a laser beam that is used to heat and melt the material. The cutting head is where the beam follows the intended pattern and a computer controls the motion so that it may be repeated.

Types of Tube and Pipe Laser Cutting Machines

CO2 Laser Cutting Machine

– This type of laser uses a gas mixture to generate the laser beam.

– They are best suited for cutting materials excluding metals such as wood, acrylic, and other kinds of plastics.

– They also perform well on metals but they are slightly slower than the fiber lasers most of the time.

Fiber Laser Cutting Machine:

– Fiber lasers employ the optical fibers as the laser active medium and in generating as well as amplifying the laser beam.

– These are ideal for metal cutting and are suitable on stainless steel, aluminum and even brass among other materials.

– These machines are faster and less energy consumptive than CO2 lasers; thus suitable for large production.

Differences and Applications

Non-metallic materials work very well with the CO2 Laser Cutting Machines, although the machines are suitable for cutting most materials. They are normally incorporated in areas such as signage and furniture, and plastic processing sectors.

In understanding the use and procurement of fiber laser cutting machine when it comes to metal cutting, it is beautiful to get that these machines are famous due to the fact that they are fast and efficient. They are used mostly in automotive, aerospace, as well as heavy industries that rely on metal cutting that is accurate and done at a fast pace.

Thus, it is found that both types of tube and pipe laser cutting machines have their relative advantages. Therefore, when it comes to the decision of choosing between a fiber laser and a CO2 laser it depends on the type of material and the need of an application. Knowledge of such differences assists when deciding on which machine is appropriate to use.

Key Features and Technologies

Advanced Cutting Capabilities

These are the main shades that characterize the work of tube and pipe laser cutting machines. Laser cutting machines employed here use beams that are very selective thus enabling them to make very accurate cuts. Consequently, they can create items with acceptable limits of deviation, and this is essential for areas such as aviation and automotive.

Another advantage associated with the use of SAP is that it supports the issuing of advice within the shortest time possible and with virtually no delay. Laser cutting is quicker than other cutting technologies and therefore, products can be made faster. This efficiency enhances manufacturers’ ability to serve their clients by offering goods that are of excellent quality but are also produced within tight production schedules.

Material Compatibility

With these machines, it is possible to cut practically all types of materials. It can handle steel, aluminum or copper but it can equally deal with plastic and composite. Due to this flexibility, they can be used in many types of industries.

Dimensions and thickness as well as different sizes are the crucial factors. Laser cutting machines for tubes and pipes are designed for cutting material with different thicknesses, thin-walled tubes and even thick pipes. This is especially true mainly due to the fact that the cutting head can be changed so as to focus on different diameters as well as more complex shapes in the manufacturing line.

Software and Automation

Integrating with CAD/CAM software shortens the design to the manufacturing cycle. An operator can feed the whole design into the machine and just get the exact dimensions of cuts that are required. This eliminates one major cause of inefficiencies and shortens the time that it takes for an idea to transform into a finished product.

Automation features enhance productivity. Some of the machines used in the processing of food products have automatic loading and unloading procedures to curb on times that one would need to get in to handle the process. This not only makes it time-effective but also safe because several human contacts with the cutting process are eliminated.

Quality Control

Reporting and evaluation are crucial to sustaining the quality kept within agencies and organizations. These systems give real-time analysis of the cutting process, and this turns out to be very useful if there is any aspect that requires a fix. This helps in the realization of the need to ensure all cuts are within the laid down standards.

Tree straightness is evident and another desired attribute is to maintain uniformity in the generated cuts. Some of the cutting features include; the use of enhanced sensors to regulate the power and focus of the lasers throughout the cutting process. This consistency is vital for producing parts that fit together perfectly in assembly lines and other applications.

Benefits of Using Tube and Pipe Laser Cutting Machines

Efficiency and Productivity

Reduction in Cutting Time: They take a much shorter time to cut as opposed to the conventional techniques of cutting. Due to this method of cutting, the manufacturing time is significantly reduced because the laser has the capability of making those exquisite cuts within a short span of time.

Increased Throughput: If indeed the cutting time has been improved then the throughput will also be improved. Basically, this means that they can make more parts in a short time span, fulfilling higher production call-offs.

Cost-effectiveness

Lower Operational Costs: Laser cutting machines are cheaper to run than other cutting machines because they help reduce costs and are automated. They entail lower manual operations and minimize the resorting to other surface treatments.

Minimization of Waste: These machines are accurate in their cutting and this means that they consume the least amount of material. This efficiency makes it possible to reduce the amount of raw material needed from the suppliers hence cutting more costs.

Versatility and Flexibility

Ability to Handle Complex Designs: Using laser cutting many details and complex shapes can be cut with the same efficiency as simpler forms. It would also help manufacturers work out accurate and intricate parts for different uses.

Quick Setup and Changeover Times: It also features fast and easy setup and, comes with means of minimizing downtime or setup time when switching between projects. It is useful, especially in cases where the requirements concerning the production needs can vary often.

Precision and Quality

High-quality Cuts with Minimal Post-processing: A number of operations that are normally done after cutting, cutting with a laser are comparatively fewer. It Alters how parts are produced so that there is less time consumed in the fabrication of parts to quickly be in a state of use.

Consistent Results Across Production Runs: These machines are accurate hence providing quality work every time they are used in production regardless of the number of times the same design is used. This in turn is very important in determining and ensuring the high quality and reliability of the manufactured products.

Choosing the Right Tube and Pipe Laser Cutting Machine

Factors to Consider

Application Requirements: Therefore, it is recommended that one defines the requirements of his/her application before choosing a machine. Think about the kind of material that you will cut, the density of the material and the difficulty of the cuts. The effectiveness of each machine depends on the other, it is wise to consider the capacities of the machines and relate the results to the project at hand.

Budget and ROI: Define the kind of budget you have available and the Return on Investment (ROI). Despite the fact that high-end machines have the potential to provide better features than the low-end machines the price aspect is quite higher than the later one. Estimate how soon the machine will recover its cost through the saved time and minimized losses. Thus, comparing the initial costs with long-term benefits, one should make the right choice.

Manufacturer Reputation and Support: Studies about manufacturers and their standings in the business world. Select any firm that has a reputation for manufacturing efficient and quality machines. Also, examine the level of support they provide, for instance, the warranty provided, maintenance services, and customer care services. Adequate after-sale services are very important in the overall efficiency of the machines in the long run.

Comparison of Popular Models

Key Features and Specifications: Differentiate different models depending on the parameters belonging to each model For example, differentiate models based on computers’ features and requirements. Many a time, the options are a matter of choosing between CO2 or fiber laser, power output, cutting speed, and the compatible material. These structures also referred to as load ports, computer interfaces or software modules are additional features found in some of the machines.

Pros and Cons of Different Models: There will be some advantages and disadvantages attached to each of the models. For instance, this high-powered fiber laser can be suitable for use in cutting through thick metal, yet it will dawn a higher price tag. On the same note, a CO2 laser might be cheaper and more capable of cutting non-metallic materials, but it might take a longer time to cut metals. You must consider these pros and cons depending on the requirements that you have in your office.

Customer Reviews and Testimonials

Feedback from Existing Users: It is also important to consult the blogs and forums where those who use the machines of your interest share their experiences. They can be useful for understanding how well the machine works, how durable it is and, how convenient it is to operate. Listen to comments that are frequently said, especially compliments and complaints, in order to determine satisfaction level.

Conclusion

Tube and pipe laser cutting machines are one of the most revolutionary products in this manufacturing era. They have high accuracy, fast operation, and are flexible to use, and thus are useful in automobile manufacturing, aerospace and construction. Being a prominent company in UAE, used to being Business Point International, we offer wonderful laser cutting services in the region.

The following tips should be put into consideration while choosing the appropriate machine for your use, the cost, and reputation of the manufacturer to offer what you want. To sum up, our machines apply to many sectors. They ensure high performance and productivity. Also, we provide you with the best client service so that you can get the assistance necessary for the best functioning.

Upgrade your tubes and pipes manufacturing process with laser cutting solutions. Business Point International could continue by stating that it is determined to assist you to enhance productivity and at the same time; minimize costs. Get the best in the region simply and without compromise. Contact us now to start learning and increasing your business.