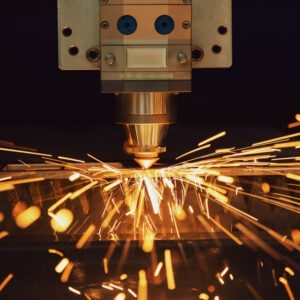

In today’s competitive market, staying ahead is a smart move to invest in the most recent technology that makes business run smoothly and faster. One of the major technologies for the processing of material which has significantly brought transformation to manufacturing is the fiber laser cutting machine. The output is very accurate hence they provide the desired results to all businesses in various sectors. Choosing the right laser cutting machine for manufacturing can be overwhelming. To help you make a decision, here’s a comprehensive guide that covers essential factors to consider before purchasing:

Buying Price:

Everywhere budget is the top consideration and it is still a crucial factor in the process of choosing the right laser cutting machine for the business. It seems essential to select affordable solutions but quality should be the key factor to consider and there should be a balance between affordability and quality. Try to set an investment level where the result will be more profitable in the long-term perspective. The lower investment may seem attractive but it’s required to consider the long-term implications. The less expensive options may have functionality issues such as frequent breakdowns or poor performance of these models, more expensive ones are more durable over time which costs companies higher maintenance budgets and production downtime. Hence, if your budget allows, aim for a machine from a trusted manufacturer where reliability is high. It is advisable for an enduring quality brand about a machine that is likely to require less maintenance with high production.

Material Thickness:

The single machine can handle different materials but its capabilities differ, material thickness may be different from the other machines. Check out your business’s machine demands and consider a machine that can cut materials with thicknesses that you usually work with. As for the thickness of materials that can be cut effectively by laser cutting machine. It’s also highly important to do the evaluation of the maximum but also minimum thicknesses that the laser can handle. Thick material cutting could be the advantage that machines have but occasionally the slicing may be not so accurate. When it comes to thin materials and the finished products should be as precise as the industry wants them to be. On the contrary, machines manufactured specifically for fine materials and not for thick materials, are imprecise and weak if a machine for thick materials is required to be used. Consequently, the choice of a suitable machine is quite necessary to have in mind the fact that it must be able to perform the full set of operations and range of materials you work with.

Part Sizes:

Choose a machine where the cutting area is large enough to handle your specifications yet still runs at peak efficiency. The dimension of the cutting area is the key issue to be determined for the selection of the machine. There can be a constraint on working with large pieces or materials that do not fit into the small cutting area of a machine thus the need for multiple setups and extra production time. But at the same time a machine with a cutting area of bigger size than required is unnecessarily costly, occupies floor space and has a lowering effect on the production of your facility. Hence, it is critical to make an informed decision on the scope of your required machine and select the machine with a cutting size that provides ample space for your current and future needs.

Quality of Components:

The performance and longevity of the fiber laser cutting machine depend upon the quality of the machine components. Choosing a machine with a renowned manufacturer built using high-quality materials and components with robustness & reliability in mind. Evaluate the machine’s components directly with reliability, endurance and general performance. Components that are relatively cheap or poor quality result in inevitable premature breakdown and failure. Thus, it will cause downtime with decreased productivity and increased repair time and costs. Therefore, among various criteria to evaluate while purchasing, the brand and reputation of the manufacturer have the highest standards for the delivery of the precise output and parts and that plays an important role in the decision. Apart from that, customers can access and after-sale or customer support services which ultimately ensure the client’s long-term reliance on the products.

Materials That Can Be Cut:

The fiber laser cutting machine has versatile processing technology and it is able to achieve a high degree of accuracy for various materials of different thicknesses. It can process copper, stainless steel, brass, carbon steel, mild steel or aluminum etc. Make sure that your computer is able to handle the media type you use. Fiber laser cutters are extremely precise machines for choosing the desired material and also in terms of the multitude of cutting of various types of materials, which makes this equipment versatile for various purposes. When you are choosing the machines, it should be noted that they must be designed to work on the bulk types of materials that you mainly handle. In various cases, some machines are not as effective in cutting material of certain types or the specific thicknesses you require. That’s why it is important to match what your business needs. Additionally, consider future material requirements and select the machine that is adaptable and diverse enough to work with different demands in the future.

Low Power Consumption:

Energy efficiency is a crucial factor for businesses that look to highly reduce both operational costs and side effects on nature. Selecting the fiber laser cutting machine that is low-power consumption and has no performance degradation while processing. The decrease in energy demand is an environmental concern and also economically profitable for the business. Fiber laser cutter is naturally a more economical energy consumption process than conventional CO2 laser machines which results in reduced energy consumption level. If you are going to purchase a machine, check it is energy-efficient, equipped with advanced laser technology, power managing system respectively. With a low energy consumption option, it can make a big difference between the operational cost and the environmental impacts as productivity & performance are maintained high.

Maintenance:

The quality of your machine depends on regular maintenance thus the machine’s longevity and its optimal performance are ensured. Select a machine that has simple and clear instructions for maintenance which allows to quickly fix it. Cleaning, maintaining the right levels of lubrication and checking key component functioning lead to early prevention from processing troubles and timely identification of possible issues before escalating & increasing the costs due to repair or downtime of machines or parts. The specific thing to do before buying a machine is its easy maintenance and accessibility of essential components like head, lenses and mirrors. Subsequently, pick a supplier that delivers extensive support services and provides maintenance training as well as quick availability of replacement parts. Attending regular repairs and getting a machine with sufficient after-sales support helps to control the downtime, increase the life expectancy of your tool and will have consistent performance for a much longer time.

Beam Path:

The design of the beam path determines the quality of the cut and its overall cutting speed. Look out for machines that have properly designed beam paths by which energy can be lost minimally with the uniform cutting quality achievable for different types of materials. Among all other important parts, the beam path is highly regarded as the accuracy and effectiveness of a fiber laser cutter. The energy conservation and beam quality are maintained by the optimal beam path which results in less energy loss, the smoothness of the cuts, the fewer kerf widths and the high cutting speed. When evaluating machines, consider the design of the beam, integrated beam delivery systems, precision optics and advanced beam control technologies. Choose an efficient machine that has a high quality and reliable beam path as well whose performance is consistent under different conditions of the materials and cutting. From among various machine models, pick the one that offers superior quality of cutting and the highest productivity with reduced material wastage rates that ultimately maximize the return on your investment.

Advanced Technology:

The advanced features of the fiber laser cutting machine reduce the downtime due to low productivity and performance. It has features such as automated handling of materials, real-time monitoring, adaptive cutting algorithms which have a large impact on process efficiency and workflow automation. Technology advances have changed cutting ability to perform faster, more precise and more economical cutting processes. Additionally, it has features like operation streamlining, productivity improvement and efficient performance compatibility. The automatic material handling system will help to cut the loading and unloading time, also real-time monitoring, display of machine performance and process optimization will be the added advantages. Adaptive cutting algorithms that optimize machines for the specific properties of materials, cutting parameters are also automatically adjusted in real-time thus boosting efficiency and level of quality. By investing in a cutting-edge machine with qualitative technology, one can run ahead of competition, raise the production rate and produce really exciting output in an extensive range of applications.

User-Friendly Interface:

Consider the simplicity of operation and convenience of the machine while operating. The use of a user-friendly interface that provides easy-to-use controls can also help in smoothing production flow and assist in the learning ability of operators which is vital in bringing an improvement in production. The user interface is the core element that influences both usability and operation workflow. Easy to use interface having logical, understandable buttons and with simple menu structure that allows for simple machine operation and requires less time to train and install. Information such as the control panel as well as the programmability and usability of the touchscreen display and software interface should be evaluated when purchasing machines. Additionally, note the presence of personalized presets, a demonstration screen, and a remote monitor device that optimize the user experience as well as workflow. Moreover, just select a machine that comes with detailed, well-programmed training and support programs to guarantee that your team can adequately operate the equipment and fully use its potential. With a well-selected machine that has a user-friendly interface, can able to charge less downtime, gain efficiency and make high-quality products consistent, without minimal effort.

Customer Support and Training:

Choose a manufacturer who gives technical support, should include many things about the production regardless of your level of knowledge. Training that is specific to the machines properly allows the team to effectively control the machines, solve their most common problems and achieve their full potential. The investment of a fiber laser cutting machine is a big decision, it is essential to be supported through the entire system and well-trained people to accomplish the objective of the equipment. Pick a supplier who has skills in fixing sourced problems and instruction in the upkeep of the machines. The training staff ensures that your people are operations aware, can identify and rectify most of the common troubles and perform the daily care & maintenance operations. Moreover, look for suppliers that offer readily available replacement of parts, quick and responsive after-sales services that will assist you in cutting on downtime and will keep your operations running as usual. By partnering with a supplier that is customer support-focused and training are the things that they prioritize, you can get maximum return from the purchase of a laser cutting machine with fiber laser technology.

Wrapping Up

It’s time to delve into the possibilities and choose a fiber laser cutting machine among many choices available in the market that match perfectly your business specifications and purpose. While material cost is important, do not sacrifice the quality of the output, reliability and the need for long-term value in favor of temporary cost savings. Through implementing the apt machinery, you will expand your business to a greater extent in the industry and it is an already competitive business world. Finally, finding the correct laser cutting machine for your company needs analysis of components such as the purchasing price, material thickness, part sizes, quality of components, compatible materials, beam path design, technological progress, user-friendliness, customer service and training programs. The above factors, when considered, can help you choose productively in a business that has positive efficiency as well as returns. Business Point International, we are the leading supplier of industrial machines in the UAE. Reach out to us for more information!